Hurst Boiler S400-1S-0400-0250 Three Pass Wet Back Packaged Scotch Marine Boiler (Steam Version)

Technical Specification

- Make: Hurst Boiler

- Model code: S400-1S-0400-0250

- Series: Series 400

- Type: Fire tube

- Design pressure: 17.24 bar

Boiler is of the three-pass, wetback scotch type, built in accordance with the requirements of the ASME Code, and listed by the National Board of Boilers and Pressure Vessel Inspectors Operating & limit pressure control Modulating pressure control Water column with gauge glass probe typecombination low water cut-off and pump control Stack Thermometer Water column drain valve Safety relief valve(s) per ASME code Uses the latest HVACR technologies and is ideal for all commercial and industrial applications

Read more| Make | Hurst Boiler |

|---|---|

| Manufacturer | Hurst Boiler & Welding |

| Category | Ships' equipment and fittings>Boilers |

| Model code | S400-1S-0400-0250 |

| Series | Series 400 |

| Type | Fire tube |

| Design pressure | 17.24 bar |

| Steam capacity | 13800 tons/hr |

| Power source | fuel oil |

| Height | 115 inch |

| Width | 109 inch |

Product description

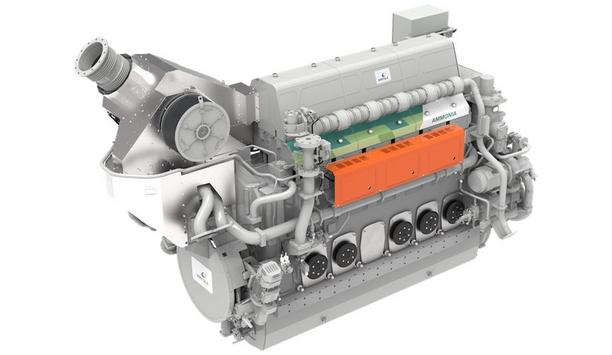

Introducing the Series 400 boiler by Boiler & Welding Co., Inc., an advanced solution for high-pressure applications in the maritime industry and beyond. This robust boiler boasts a three-pass Scotch Marine design coupled with innovative wetback construction, effectively eliminating the need for maintenance-heavy refractory rear doors and baffles.

Key Features

- Capable of handling capacities from 30 to 1500 BHP and pressures from 15 to 300 PSI.

- Fireside heating surface ranging from 150 to 1250 square feet.

- Modular, skid-mounted design for seamless installation and setup.

- Constructed and stamped in compliance with ASME Boiler Codes, ensuring reliability and safety.

Technical Advantages

The wetback construction of the Series 400 ensures enhanced heat absorption and rapid water circulation, resulting in improved efficiency and reduced operating costs. The full wetback design prevents the common issues of refractory deterioration and baffle leakage found in dryback designs, thereby extending the boiler's operational life.

Ideal Use Cases

Suitable for high-pressure steam applications, the Series 400 excels in industrial environments requiring reliable and efficient heating solutions. From marine vessels to large manufacturing facilities, this boiler offers consistent performance with lower downtime, making it an essential component for demanding operational settings.

Backed by years of meticulous engineering, the Series 400 is designed for longevity, offering benefits to professionals looking for dependable performance and minimal maintenance expenses.