Hurst Boiler S400-1S-0600-0250 Three Pass Wet Back Packaged Scotch Marine Boiler (Steam Version)

Technical Specification

- Make: Hurst Boiler

- Model code: S400-1S-0600-0250

- Series: Series 400

- Type: Fire tube

- Design pressure: 17.24 bar

Boiler is of the three-pass, wetback scotch type, built in accordance with the requirements of the ASME Code, and listed by the National Board of Boilers and Pressure Vessel Inspectors Operating & limit pressure control Modulating pressure control Water column with gauge glass probe typecombination low water cut-off and pump control Stack Thermometer Water column drain valve Safety relief valve(s) per ASME code Uses the latest HVACR technologies and is ideal for all commercial and industrial applications

Read more| Make | Hurst Boiler |

|---|---|

| Manufacturer | Hurst Boiler & Welding |

| Category | Ships' equipment and fittings>Boilers |

| Model code | S400-1S-0600-0250 |

| Series | Series 400 |

| Type | Fire tube |

| Design pressure | 17.24 bar |

| Steam capacity | 20700 tons/hr |

| Power source | fuel oil |

| Height | 127 inch |

| Width | 121 inch |

Product description

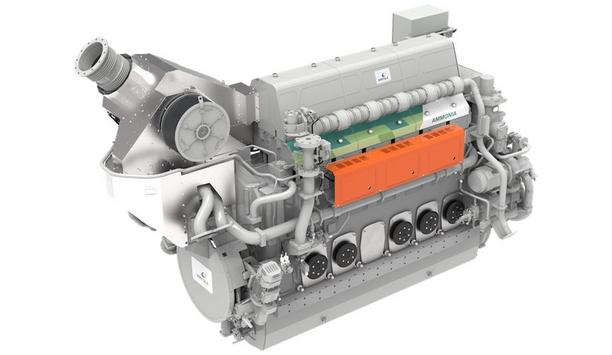

The Series 400 Boiler by Hurst Boiler & Welding Co., Inc., combines cutting-edge engineering with robust performance to deliver a reliable solution for high-pressure industrial applications. This boiler features a three-pass Scotch Marine design with a unique wetback construction, ensuring enhanced durability and energy efficiency.

Key Features

- Capacities: Ranges from 30 to 1500 Boiler Horsepower (BHP).

- Steam Pressure: Capable of operating from 15 to 300 PSI.

- Hot Water Systems: Suitable for Section I and Section IV requirements.

- Construction: Robust wetback design eliminating issues with refractory rear doors and baffles.

- Fuel Flexibility: Configured for natural gas, propane (LP) gas, and multiple fuel oil options.

- Factory-Assembled: Skid-mounted and modular packaged for straightforward installation.

Ideal Use Cases

The Series 400 Boiler is ideally suited to industries requiring high-pressure steam and hot water, such as manufacturing, food processing, and chemical plants. The wetback design minimises downtime due to maintenance, making it an asset in continuous production environments.

Technical Advantages

- Eliminates the need for costly refractory maintenance due to its innovative design.

- Provides superior water circulation and heat absorption levels, enhancing efficiency.

- Separate rear tube sheets to reduce stress, ensuring longer component life.

Standard Safety and Control Features

The boiler is equipped with certified safety relief valves, pressure and temperature controls, and low water cut-off mechanisms, all in compliance with ASME standards. Optional features include modulating controls for precise operational management.

For industrial applications requiring reliable and efficient high-pressure steam and hot water boilers, the Series 400 Boiler stands as a premier choice, ensuring performance with minimal maintenance disruption.