Hurst Boiler S400-4W-0030-0030 Three Pass Wet Back Packaged Scotch Marine Boiler (Hot Water Version)

Technical Specification

- Make: Hurst Boiler

- Model code: S400-4W-0030-0030

- Series: Series 400

- Type: Fire tube

- Design pressure: 2.07 bar

Boiler is of the three-pass, wetback scotch type, built in accordance with the requirements of the ASME Code, and listed by the National Board of Boilers and Pressure Vessel Inspectors Operating & high limit temperature control Modulating temperature control Low water cut-off control with manual reset Stack Thermometer Hot water return baffle for shock resistance Combination pressure and temperature gauge Safety relief valve(s) per ASME code Uses the latest HVACR technologies and is ideal for all commercial and industrial applications

Read more| Make | Hurst Boiler |

|---|---|

| Manufacturer | Hurst Boiler & Welding |

| Category | Ships' equipment and fittings>Boilers |

| Model code | S400-4W-0030-0030 |

| Series | Series 400 |

| Type | Fire tube |

| Design pressure | 2.07 bar |

| Steam capacity | 1035 tons/hr |

| Power source | fuel oil |

| Height | 55 1/4 inch |

| Width | 58 inch |

Product description

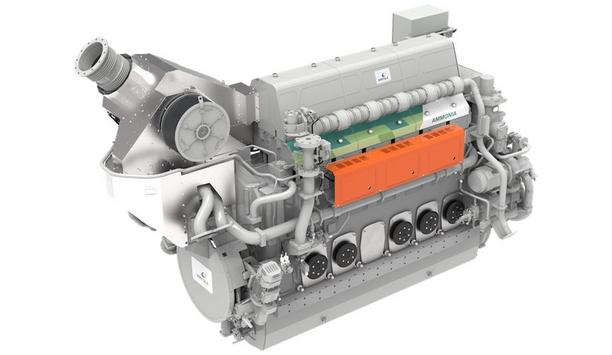

The Series 400 High-Pressure Boiler by Boiler & Welding Co., Inc. embodies a sophisticated engineering design ideal for maritime industry applications. Boasting a three-pass Scotch Marine design, this boiler utilises a wetback construction that eliminates the need for costly and deteriorating refractory rear doors and baffles between flue gas passes, enhancing longevity and efficiency.

Key Features

- Capacities ranging from 30 to 1500 BHP with outputs from 1004 to 50213 MBTU/HR.

- Steam pressure capabilities from 15 to 300 PSI, tailored for both steam and hot water applications.

- Factory assembled, skid-mounted modular package for ease of installation and maintenance.

- Compliance with ASME Code, UL, and CSD-1 standards, ensuring reliability and safety.

- Equipped with UL listed “forced draft” power burners suitable for natural gas, propane, and diesel oil.

Ideal Use Cases

The Series 400 is perfect for maritime operations that demand high efficiency and reduced maintenance. The innovative wetback design minimises issues like gas flow short-circuiting, often found in traditional dry back boilers, thus preventing high stack temperatures and enhancing overall efficiency.

Whether for high-pressure steam generation or as a reliable hot water source, the Series 400 stands out with its robust build and cutting-edge features, making it a dependable choice for demanding maritime environments.