Hyundai Heavy Industries (HHI) - Experts & Thought Leaders

Latest Hyundai Heavy Industries (HHI) news & announcements

ABS issued approval in principle (AIP) to HD Hyundai Heavy Industries (HHI) and HD Korea Shipbuilding & Offshore Engineering (HD KSOE) for a concept of a floating small modular reactor (SMR)-powered power module. The design is intended to generate electricity offshore and near shore, supporting port facilities and onshore communities. ABS completed design reviews based on the ABS Requirements for Nuclear Power Systems for Marine and Offshore Applications. Advanced nuclear technology "Floating nuclear power facilities show promise in supporting power grids, microgrids, industrial and port operations, data centres, and other uses. Additionally, today’s advanced nuclear technology has a different risk profile from traditional reactor technology with state-of-the-art designs and with lower enrichment fuels, making commercial offshore and maritime applications more viable," said Patrick Ryan, ABS Senior Vice President and Chief Technology Officer. Nuclear power barge design An official from HD Korea Shipbuilding & Offshore Engineering said: "The floating nuclear power plant is expected to play a key role in building a future powered by clean energy. We will remain fully committed to developing the necessary technologies and ensuring its successful realisation." The AIP is the second for a floating nuclear power barge design from HD KSOE and is the latest step in a long-running collaboration with ABS on nuclear technologies, including another power barge design and a groundbreaking 15k teu nuclear propelled containership.

KR (Korean Register) signed a Memorandum of Understanding (MoU) with HD Hyundai Heavy Industries (HD HHI) on June 3 during Nor-Shipping 2025 to jointly develop a very large ethane carrier (VLEC). Ethane carriers are high value-added vessels designed to transport liquefied ethane at ultra-low temperatures of around -100°C. These ships require advanced engineering capabilities and highly specialised design expertise due to the complexity of their cargo. New very large ethane carrier (VLEC) Under this joint project, HHI will take the lead in the vessel’s basic and hull design The new VLEC to be developed under this partnership will have a cargo capacity exceeding 100,000 m³. It will be designed to maximise cargo volume, while minimising changes to the main specifications of conventional vessel designs. Additionally, the vessel will be capable of transporting a variety of cargoes, such as LPG and propylene, enhancing operational flexibility and market responsiveness for ship owners. Under this joint project, HHI will take the lead in the vessel’s basic and hull design. KR will review the safety and regulatory compliance of the design in accordance with its latest structural rules for gas carriers and international standards, with the aim of granting an Approval in Principle (AiP). Korean Register and HD HHI partnership RYU Hong-Ryul, CTO and Executive Vice President at HD Hyundai Heavy Industries (HD HHI), stated, “Through the development of this next-generation vessel capable of transporting more cargo under the same conditions, we will once again demonstrate HHI’s technological leadership in the global ethane transportation market. Ultimately, we aim to deliver a sustainable solution that enhances both profitability and environmental performance for our customers.” LEE Hyungchul, Chairman and CEO of KR (Korean Register), commented, “This joint effort marks a meaningful starting point in the development of next-generation ethane carriers. KR remains committed to supporting the industry and driving innovation in future ship technologies.”

ABS issued approval in principle (AIP) to HD Hyundai Heavy Industries (HD HHI) and HD Korea Shipbuilding & Offshore Engineering (HD KSOE) for an innovative new design of a cargo handling system and fuel gas supply system. Hi-ecoGAS and Hi-neoGAS systems Named Hi-ecoGAS and Hi-neoGAS, the systems are designed to handle boil-off gas in dual-fuel engines on gas carriers. The innovative approach has an optimised fuel gas supply system for feeding the fuel gas to the dual-fuel engine, or an LNG sub-cooling system for handling boil-off gas. ABS completed design reviews based on class and statutory requirements Presented at the 60th anniversary of the Nor-Shipping maritime trade fair, the AIP signifies the Hi-ecoGAS and Hi-neoGAS systems are technically feasible and ready to take the next step to commercialisation. ABS completed design reviews based on class and statutory requirements. Boil-off gas “Boil-off gas can present significant challenges to storage and transportation, which can lead to safety hazards. ABS is proud to use their expertise as the world’s renowned classification society for gas carriers to support HD HHI and HD KSOE with these new designs,” said Patrick Ryan, ABS Senior Vice President and Chief Technology Officer. “Hyundai Heavy Industries (HHI) has recognised that developing a fuel gas supply system (FGSS) that minimises methane slip is a critical step in the era of decarbonisation. HHI expects that its newly designed cargo handling and fuel gas supply system will make a significant contribution toward achieving the International Maritime Organization’s (IMO) 2050 Net Zero target,” said Hong-Ryeul Ryu, Executive Vice President, CTO of HD HHI’s Shipbuilding Business division. Development of Hi-ecoGAS and Hi-neoGAS “The development of Hi-ecoGAS and Hi-neoGAS strengthens HD KSOE’s and HHI’s ability to meet the evolving needs of global ship owners. As a major provider of advanced shipbuilding solutions, HD KSOE remains committed to driving innovation and leading the global shipbuilding industry,” said Kwang-Pil Chang, Senior Vice President and Chief Technology Officer of HD KSOE. ABS is the world’s premier classification society for gas carriers with more than 50 years of experience building and classing gas carriers of every type and size, from the transport of liquefied natural and petroleum gas to the next generation of gas carriers.

Insights & Opinions from thought leaders at Hyundai Heavy Industries (HHI)

As regulations on emissions become more stringent, more companies and organisations in the maritime industry will likely start to use methanol as a cleaner and more sustainable fuel. Methanol Methanol is a promising alternative fuel for the maritime industry due to its potential to reduce greenhouse gas emissions, increase energy security, and improve air quality. The future of methanol as a maritime fuel depends on several factors, including regulatory policies, technological advancements, and the availability and cost of methanol. Production One of the main advantages of methanol as a maritime fuel is that it can be produced from a variety of renewable and non-renewable sources, such as natural gas, coal, and biomass. Methanol can be produced using CCU technologies, which can help reduce the carbon footprint Methanol can also be produced using carbon capture and utilisation (CCU) technologies, which can help reduce the carbon footprint of the maritime industry. In addition, methanol is relatively easy to transport and store, making it an attractive option for use in marine vessels. Availability Methanol can be stored at room temperature and can be transported using existing infrastructure, such as pipelines and tankers. The availability of methanol at ports is an issue. In 2020, the Methanol Institute confirmed that methanol is already available in more than 100 ports around the globe and that 47 of those ports have storage facilities of over 50,000 metric tons. A further 66 ports are also storing methanol. Use of methanol in reducing GHGs Methanol can reduce greenhouse gas emissions and meet new emissions regulations when used as a marine fuel in various ways, including: Blending with marine diesel oil (MDO): Methanol can be blended with MDO to produce Methyl Diesel Fuel (MDF). MDF can be used in compression ignition engines that typically run on MDO or heavy fuel oil. Direct injection: Methanol can also be used as a direct injection fuel. In this case, methanol is injected into the engine’s combustion chamber and burned as the primary fuel. Methanol can be used in both spark-ignited and compression-ignited engines. Dual-fuel engines: Methanol can also be used in dual-fuel engines. In this case, methanol is injected into the combustion chamber along with another fuel, such as diesel. Diesel acts as the pilot fuel to ignite the methanol, which is burned as the primary fuel. Pros and cons Methanol is highly toxic and flammable, so it requires careful handling and storage to ensure safety One advantage of using methanol as a maritime fuel is that it has a high-octane rating, which can improve engine performance. Methanol is also relatively easy to produce, and it can be made from renewable sources such as biomass. However, methanol is highly toxic and flammable, so it requires careful handling and storage to ensure safety. Environmental benefits Methanol has several environmental advantages over traditional maritime fuels such as heavy fuel oil and marine diesel oil. These advantages include: Lower greenhouse gas emissions: Methanol has a lower carbon content than traditional maritime fuels, which means it produces fewer greenhouse gas emissions when burned. Methanol can reduce greenhouse gas emissions by up to 15% compared to traditional fuels. Reduced air pollution: Methanol also produces fewer emissions of harmful air pollutants such as nitrogen oxides (NOx) and particulate matter (PM) when burned. Methanol can reduce NOx emissions by up to 60% and PM emissions by up to 95% compared to traditional fuels. Biodegradability: Methanol is biodegradable, which means it can break down naturally in the environment. This is important in case of any accidental spills or leaks that may occur during fuel handling and transportation. Renewable source: Methanol can be produced from renewable sources such as biomass, which means it can be a sustainable alternative to traditional maritime fuels. Energy efficiency: Methanol has a high energy content per unit of weight, which means it can provide more energy per unit of fuel compared to traditional fuels. This can lead to improved energy efficiency and lower fuel consumption. Maritime applications Stena Line has converted one of its ferries, the Stena Germanica, to run on methanol Overall, using methanol as a maritime fuel can help reduce the shipping industry's environmental impact and promote more sustainable and responsible practices. Several companies and organisations have started using methanol for maritime applications. Stena Line, a Swedish ferry operator, has converted one of its ferries, the Stena Germanica, to run on methanol. The ferry operates between Kiel, Germany, and Gothenburg, Sweden. Nominal capacity In addition, Maersk Line, the world's largest container shipping company, has announced plans to use methanol as a marine fuel. In October 2022, Maersk announced it has ordered a further six large ocean-going vessels that can sail on green methanol. The six vessels will be built by Hyundai Heavy Industries (HHI) and have a nominal capacity of approximately 17,000 containers (Twenty Foot Equivalent - TEU). They will replace the existing capacity in the Maersk fleet. With the order, Maersk has in total ordered 19 vessels with dual-fuel engines able to operate on green methanol. Methanol engines MAN Energy Solutions, a provider of marine engines, has developed methanol engines for use in maritime applications. The engines can be used in both propulsion and auxiliary power applications. Methanol-based two- and four-stroke solutions will be relevant for the complete MAN Energy Solutions marine engine portfolio. Typical examples of the application of four-stroke engines include container ships, ferries, fishing or cruise vessels, as well as offshore solutions. Future adoption Adoption of methanol will depend on cost, availability, and the development of regulatory frameworks Stationary solutions might also be a possible area for methanol applications, for example, for small islands that lack natural gas infrastructure. However, the wider adoption of methanol as a maritime fuel will depend on several factors, including the cost of methanol production, the availability of methanol infrastructure, and the development of regulatory frameworks to support its use. Nevertheless, the future of methanol as a maritime fuel looks promising, as it offers a potential solution to the maritime industry's environmental and energy security challenges. Flexible in use Battery electric propulsion is another potential alternative to traditional maritime fuels, but it is limited by the current state of battery technology, which makes it difficult to achieve long-distance, large-scale shipping operations. Methanol can offer a longer range and greater flexibility than battery electric propulsion while still reducing emissions. Overall, while methanol is not a perfect solution, it offers several advantages over other maritime fuels and has the potential to play a significant role in reducing the environmental impact of the shipping industry.

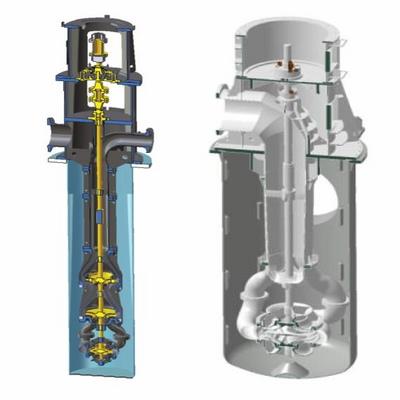

Hyundai Heavy Industries XCAF Cable Free Submersible Pump

Hyundai Heavy Industries VWDB Vertical Multi Stage Pump

Hyundai Heavy Industries VK / VA Vertical Single Stage Pump