Security

News

The 10th annual Maritime Standard Tanker Conference 2025 will be held on Thursday, 30th October at the iconic Atlantis, The Palm, Dubai. Aimed at key decision makers and opinion formers within the tanker shipping business, the event takes place at an uncertain time for the industry, given economic volatility and a host of geopolitical issues. Tough environmental regulations There is also growing pressure to comply with tough environmental regulations There is also growing pressure to comply with tough environmental regulations, presenting a series of technical and commercial hurdles. While there is long term optimism about the future of the industry, there are certainly short term challenges, and how best to navigate through these will be the core, overarching theme of this year’s conference. Tanker shipping negotiates challenging market headwinds. Session 2 in the afternoon will have the theme of “Boosting operational efficiency while maintaining a focus on green shipping.” This session will focus on the key issues facing tanker shipowners and operators in terms of day-to-day operations, and the solutions available to them. Environmental regulatory changes This will look at how best to accommodate environmental regulatory changes, embrace technology advances in areas such as digitalisation and AI to best effect, and also to address growing seafarer and vessel safety concerns. This session will hear from a range of speakers from various sectors, including ship repair, maritime insurance, law, bunker supply, ship management, security, information technology, as well as tanker owners and operators. Topics proposed for inclusion include: Embracing new generation tanker designs Retrofitting for a green, profitable future Harnessing the power of AI to strengthen commercial and operational resilience Safety at sea - tackling the renewed threat of piracy, cyber security and other safety challenges facing the industry Carbon capture as a viable future option for tanker shipping Developing solid financial foundation to support future growth. Speakers will also examine the importance of creating alternative fuel supply networks and debate which fuel is the best option for dual fuel operations in different market segments.

AdvanTec Marine is pleased to announce a major milestone: both its Canadian manufacturing facility in British Columbia and its Oregon, USA facility are now certified to produce fire-rated marine doors. With the Canadian site receiving MED Wheel Mark certification — making it the only such facility in Canada — AdvanTec now proudly holds fire-rated door certifications on both sides of the border. Commitment to safety and innovation New chapter as AdvanTec strengthens its position as a trusted partner for shipbuilders worldwide This achievement underscores the company's unwavering commitment to safety and innovation, and marks an exciting new chapter as AdvanTec strengthens its position as a trusted partner for shipbuilders worldwide. "This dual certification across both our Canadian and U.S. facilities allows us to better serve our customers with shorter lead times, tariff-free manufacturing, and complete compliance with international safety regulations," said Dean Robinson, Director of Products & Business Systems, AdvanTec Marine. Highest international standards AdvanTec Marine offers A0, A15, A30, and A60 fire-rated doors from both its Canadian and U.S. facilities. These doors are engineered to meet the highest international standards and are available in both Watertight and Weathertight configurations: Watertight fire-rated doors are designed for watertight bulkheads below the freeboard deck and are capable of withstanding static head pressure from either side. Weathertight fire-rated doors offer robust protection against driving rain and washdown, making them ideal for above-deck applications. Key classification society requirements AdvanTec fire-rated doors are built in accordance with the IMO 2010 FTP Code Part 3 and hold MED certification All AdvanTec fire-rated doors are built in accordance with the IMO 2010 FTP Code Part 3 and hold MED certification by DNV, ensuring they offer the same fire resistance as the structural bulkhead into which they are installed. Additionally, the doors meet key classification society requirements, including Lloyd's Register (LR), DNV, Bureau Veritas (BV), and American Bureau of Shipping (ABS). AdvanTec's investment in certification "This dual certification across both our Canadian and U.S. facilities allows us to better serve our customers with shorter lead times, tariff-free manufacturing, and complete compliance with international safety regulations," said Dean Robinson, Director of Products & Business Systems at AdvanTec Marine, adding "We're proud to support shipbuilders with reliable, certified fire-rated doors." With growing global demand for compliant marine safety solutions, AdvanTec's investment in certification and in-house manufacturing reinforces its commitment to innovation, safety, and service across the marine industry.

Kongsberg Discovery has decided to start production of HUGIN, an autonomous underwater vehicle, in the U.S. This strategic decision reflects the commitment to supporting the growing demand for advanced subsea technology in the U.S. market. Kongsberg Discovery is a global pioneer in advanced robotics and sensor technology, enabling the mapping, monitoring, and surveying of the ocean environment. This is achieved using advanced hydroacoustic, optical, and scientific sensors, connected to sophisticated data networks and visualisation tools. Autonomous underwater vehicles The company has now decided to start producing autonomous underwater vehicles in the U.S. The company has now decided to start producing autonomous underwater vehicles in the U.S. "This strategic decision reflects our commitment to support the growing demand for advanced subsea technology in the U.S. market," says Martin Wien Fjell, President of Kongsberg Discovery. He adds, "By establishing domestic production capabilities, we aim to strengthen our U.S.-based supply chain and enhance our responsiveness to the evolving needs of our government and commercial customers. This demand has increased as global tension has risen." Utilise opportunities Kongsberg Discovery has already delivered HUGIN to the U.S. Navy and other organisations within the government, commercial, and academic sectors. Due to increased demand from the defence sector and growing recognition of their unmanned underwater vehicles' (UUV) capabilities among U.S. Navy customers, a strategic decision has been made to expand investment in the United States. According to Fjell, the company’s ongoing development has resulted in systems that address a range of high-priority naval requirements. “Kongsberg Discovery plans to start the HUGIN production at our existing facility in Lynnwood, Washington. The future production facility is yet to be decided,” he says. Real-world missions Presently, there are 12 navies using HUGIN in real-world missions, such as Subsea and Seabed Warfare Presently, there are 12 navies using HUGIN in real-world missions, such as Intelligence Preparation of the Operational Environment, Mine Counter Measure, Subsea and Seabed Warfare, and seafloor mapping operations. “We are excited to bring our many years of AUV experience in support of the U.S. military. This is a major project that supports the management’s decision to invest in a production and assembly facility for HUGIN in the US,” Fjell continued. Sonar mission systems In the United States, Kongsberg Discovery U.S. (formerly Kongsberg Underwater Technology LLC) has been the exclusive supplier and integrator of Kongsberg Discovery (KD) sonar equipment used for oceanographic survey and research missions, from the shallowest to the deepest parts of the oceans. KD U.S. has installed and maintained this equipment on new or repurposed vessels for projects each year since 1989. Currently, the sonar mission systems on over 30 ships in the U.S. government and academic fleets are supported throughout their lifespan, including the T-AGS 60 class and T-ARC, as well as achieving significant commercial success. In addition to science mission sonar packages, KD U.S. has provided the U.S. government with uncrewed platform solutions. KONGSBERG has around 900 employees at 15 locations in the U.S. and Canada. All business areas are represented in the U.S., and the strategy going forward is to further increase its presence in North America.

MariTrace, a global pioneer in maritime intelligence and ship-tracking technology, announces a strategic partnership with Strickland Services Limited, a Nigerian-owned offshore logistics organisation and specialist provider of maritime security vessels, effective immediately. With over 25 years of experience operating in some of the world’s most volatile waters, Strickland Services require the most secure, consistent and reliable positional data for its clients, all around the world. The new collaboration sees ten of Strickland’s logistics support vessels being equipped with Mercury – MariTrace’s innovative, encrypted tracking solution designed for uninterrupted vessel visibility in real-time – even in AIS black spots. Offshore oil and gas waterways Strickland’s fleet plays a critical role in protecting offshore assets and personnel for blue-chip energy clients Operating globally including waterways like the Gulf of Guinea, a region with one of the ocean’s most volatile maritime corridors due to ongoing piracy and geopolitical instability, Strickland’s fleet plays a critical role in protecting offshore assets and personnel for blue-chip energy clients including Shell, ExxonMobil and Total. With strategic operations based in Port Harcourt and Lagos, Strickland delivers armed escort, platform security and subsea support globally across offshore oil and gas waterways. Ongoing risks in challenging waters In response to the ongoing risks in these challenging waters, Strickland has integrated Mercury – a plug-and-play, highly granular tracking device developed by MariTrace – to strengthen its operational oversight and client assurance. By using Mercury, Strickland’s crews, clients and command teams can be assured of seamless tracking and data continuity, confidentially. MariTrace interface upon reconnection Insurance and management companies can also continue to track their own vessels Mercury, designed and launched by MariTrace in 2024, is a compact, discreet and powerful onboard tracking device that continues to transmit positional data even when AIS coverage drops or is turned off – a common challenge in remote or hostile waters. The system detects connectivity loss, caches data locally and automatically syncs with the MariTrace interface upon reconnection, ensuring that vessel movements are never lost. Insurance and management companies can also continue to track their own vessels, without public knowledge, with explicit approval via the MariTrace platform. Safety and accountability in offshore logistics Thomas Owen, CEO of MariTrace, comments, "Strickland Services operate in some of the world’s highest-risk territories, where traditional tracking systems are simply not reliable enough. Mercury provides the very best peace of mind, particularly in these regions – ensuring uninterrupted operational oversight, improved response coordination and ultimately, keeping vessels and crews safer." He adds, "We’re proud to support Strickland’s mission for the highest standard of safety and accountability in offshore logistics, with technology designed for the realities of modern maritime security." Mercury across Strickland’s fleet The system integrates with onboard tracking systems like GPS as well as AIS networks via NMEA 0183/2000 Incorporating Mercury across Strickland’s fleet allows for real-time global positioning updates at one-minute intervals by default, with the option to increase transmission frequency when required. The system integrates with onboard tracking systems like GPS as well as AIS networks via NMEA 0183/2000, delivering highly secure, granular data – delivered live to the MariTrace interface or API, which is accessible to authorised users such as operations managers, insurers or security teams. Real-time view of nearby AIS targets The AIS data collected onboard by each vessel is also displayed directly in the MariTrace interface. This gives shore-based operators live information on the position of the host vessel, as well as a real-time view of nearby AIS targets, including support vessels – even in AIS black spots – which significantly enhances maritime domain awareness. Temidayo Amure, ICT Coordinator of Strickland Services Limited, states, "At Strickland, safety, security and visibility are non-negotiable. Our clients operate in some of the world’s most volatile maritime zones, and they rely on us to protect their assets with the best tools available." Temidayo Amure adds, "Mercury was the perfect choice for us to install across key vessels – thanks to its real-time, reliable tracking. MariTrace delivered exactly what we need: full visibility, even when AIS drops out. For us, it’s about leadership, accountability and giving clients total peace of mind." Mercury’s integration with the MariTrace platform Mercury’s integration with the MariTrace platform provides Strickland with a full suite of maritime intelligence tools For chartered vessels, Mercury positions can be shared with other MariTrace users to offer the ultimate support and monitoring, when permission is granted. This means that if a Strickland vessel is supporting a third-party vessel and they have a MariTrace account, they can access these Mercury positions and provide a more cohesive service to their clients who are already utilising the platform. In addition to real-time tracking, Mercury’s integration with the MariTrace platform provides Strickland with a full suite of maritime intelligence tools – including route risk analysis, geofencing alerts, maritime incident feeds and historical data going back to 2015. This maximises fleet monitoring, as well as strategic decision-making, regulatory compliance and emergency readiness. MariTrace and Strickland’s partnership With piracy risks and other illicit threats persisting on the western coast of Africa and beyond, clients are demanding ever-higher standards of protection. MariTrace and Strickland’s partnership is a new benchmark, setting the standard for vessel security oversight in high-risk waters. Mercury marks a significant step forward in tactical certainty and greater confidence for logistics support fleets tasked with safeguarding energy infrastructure around the world.

Expert commentary

The global maritime surveillance market is projected to grow from $21.9 billion in 2023 to $ 42.7 billion by 2033. This growth is being driven by increasing global trade, maritime security concerns, and the adoption of advanced surveillance technologies such as radars, drones, and satellite monitoring systems. Moreover, the global shipping industry is now on the frontlines of a new kind of conflict — one defined by economic coercion, shadow fleets, and contested logistics – a durable competition where adversaries seek control and influence over global supply chains. As tariff regimes expand and national security policies increasingly target commercial vessels, maritime operators are being forced to navigate a risk environment shaped more by geopolitics than wind and weather. Infrastructure of global trade Trade disruptions are no longer accidental by products of diplomacy — they are deliberate policy levers. Tariff escalation between the U.S. and China, sanctions on Russian oil, and Houthi attacks in the Red Sea are not isolated threats; they signal a new normal in which governments treat the shipping industry as a tactical asset. From China's military-civil fusion shipbuilding policies to LOGINK, its state-run maritime surveillance network, the very infrastructure of global trade is becoming entangled in nation-state agendas. Contested logistics: Struggle for global economic stability The current maritime threat landscape involving contested logistics contains strategic positioning The current maritime threat landscape involving contested logistics encompasses strategic positioning across critical chokepoints and infrastructure. The statistics are sobering: major shipping companies reported traffic through the Suez Canal dropped by 66% as of September 2024 due to Houthi attacks, with J.P. Morgan estimating shipping costs have surged significantly, particularly from Asia to Europe, nearly five-fold. Regional maritime security issues These developments illustrate how foundational industries, such as shipbuilding, semiconductors, and rare earth minerals, have become battlegrounds in a broader geopolitical struggle where a cascade of effects have the potential to destroy economies. For example, a military blockade of Taiwan — where Taiwan Semiconductor Manufacturing Corporation operates — would impact every company dependent on advanced semiconductors. This interconnectedness means that what may, on the surface, appear to be regional maritime security issues, can be much more — the potential for global economic disruption across multiple industries. Monitoring of Arctic fleet movements Shadow fleets operated by sanctioned states rely on tactics such as false flagging, frequent ownership changes New threat vectors are coming into focus as the seas expand. As the polar ice caps melt, new Arctic shipping lanes are opening, with a large portion of traffic driven by Russian vessels. These routes present unique surveillance challenges due to their remote nature and the limited presence of traditional maritime enforcement bodies. Monitoring of Arctic fleet movements and infrastructure developments is essential for maintaining security in this emerging corridor. Concerns about dual-use capabilities and strategic readiness Shadow fleets, illicit networks, and military-grade commercial vessels represent real risks, posing challenges in the areas of regulatory compliance, insurance viability, and operational safety. Shadow fleets operated by sanctioned states rely on tactics such as false flagging, frequent ownership changes, and manipulations of the Automatic Identification System (AIS). By turning off transponders, spoofing locations, or falsifying data, these vessels can effectively vanish from traditional tracking systems. This disappearance makes ships harder for authorities to trace and easier for adversaries to exploit for sanctions evasions and/or covert logistics. China's commercial fleets increasingly mirror military standards, raising concerns about dual-use capabilities and strategic readiness under the guise of trade. The need for a new risk framework To navigate this new threat landscape on the high seas, organisations must adopt a new kind of visibility For logistics and shipping pioneers, these implications are profound. This is no longer about simply avoiding sanctioned cargo — it's about forecasting how governments will act and how quickly those actions can alter operations. Vessels may be commandeered, sanctioned, or rerouted without warning. Insurance may evaporate. Contracts may become liabilities. To navigate this new threat landscape on the high seas, organisations must adopt a new kind of visibility — one that models the cascading effects of tariffs, military requisition policies, and enforcement shifts. This is where Open-Source Intelligence (OSINT) becomes indispensable. Real-time context on geopolitical risks OSINT draws from publicly available data -- including satellite imagery, port registries, and social media — to provide real-time context on geopolitical risks. It can be used to track vessel flagging and ownership changes, monitor transshipment hubs, and surface anomalies in crew rosters and employment histories — indicators often tied to sanctions evasion or illicit activity. AIS anomaly detection reveals when ships "go dark." Satellite imagery exposes vessels operating without transponders. Tracking shifts in vessels' flagging or changes in crew manifests can signal risk before it hits operations. Early indicators of disruption OSINT supports risk modelling by revealing trends like flag-of-convenience usage, secondary insurance For insurers and regulators, OSINT supports risk modelling by revealing trends such as flag-of-convenience usage, secondary insurance underwriting in high-risk zones, and affiliations with known bad actors. OSINT doesn't just enhance compliance — it enables foresight, empowering industry players to anticipate when and where governments will act. Now, tariff announcements, sanction designations, and strategic military exercises are not isolated datapoints — they're potentially early indicators of disruption. Maritime situational awareness is a business imperative The age of separating business risk from political risk is over. Global shipping is now a domain of contested logistics where the rules can change as fast as a sanctions update or new enforcement directive. Companies that integrate OSINT into their operational planning gain the ability to model and mitigate threats proactively. Those that don't may find themselves caught in the wake of potential financial, operational, and reputational harm. The shipping industry needs access to the same kind of threat modelling governments use to act. In an era of growing complexity, the role of OSINT in securing global shipping networks cannot be overstated.

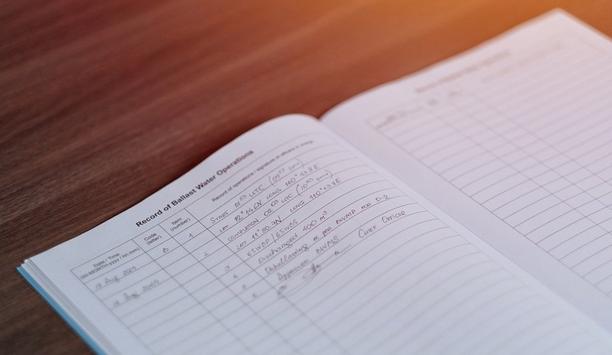

When the Ballast Water Management (BWM) Convention came into force in 2004, it was in response to a crisis we couldn’t afford to ignore—one where invasive aquatic species, carried silently in ships’ ballast tanks, were devastating marine ecosystems. Now, two decades later, compliance with this environmental safeguard is no longer optional—and yet, as recent industry findings reveal, record-keeping failures account for 58% of compliance issues. That’s not a technology problem. That’s a documentation problem —one rooted deeply in data management practices and crew training, where small oversights lead to documentation issues, that may cascade into costly compliance failures. And that’s precisely where digital systems excel, guiding crews clearly to avoid mistakes in the first place. New ballast regulations At the IMO’s 82nd Marine Environment Protection Committee (MEPC 82), new ballast water record-keeping regulations were approved, coming into effect from 1 February 2025. These updates mark a significant tightening of documentation standards—and they could catch unprepared shipowners off guard if not acted on promptly. Why ballast water record-keeping is back in the spotlight These new updates aim to change that—and they’re stricter, smarter, and more detailed than before While MEPC 82 made headlines for advancing decarbonisation policies and ECAs in the Arctic and Norwegian Sea, it also honed in on ballast water—a topic that has quietly regained importance. The committee approved critical updates to how ballast water operations and ballast water management system (BWMS) maintenance are recorded. The goal: Enhance transparency, reduce ambiguity, and reinforce environmental protection by making records more structured, traceable, and actionable. This renewed focus is both a warning and an opportunity. In recent years, too many Port State Control detentions and inspection delays have stemmed not from hardware failures, but from poorly maintained or unclear ballast water records. These new updates aim to change that—and they’re stricter, smarter, and more detailed than before. What’s changing: Bypass scenarios and maintenance logging The revised guidelines introduce two new scenarios for vessels dealing with challenging water quality (CWQ) in ports: Scenario 3: A reactive bypass of the BWMS due to unforeseen poor water quality. Scenario 4: A pre-emptive bypass based on anticipated CWQ conditions. These additions are essential for vessels operating globally, particularly those above 400GT. They ensure that alternative operations—like ballast water exchange plus treatment (BWE + BWT)—are clearly documented. Without accurate records, even legitimate actions can fall short of compliance. Ballast Water Management Plan and OEM manuals MEPC 82 also mandates that BWMS care procedures must now be recorded directly in BWRB MEPC 82 also mandates that BWMS maintenance procedures must now be recorded directly in the Ballast Water Record Book (BWRB), in line with the ship’s Ballast Water Management Plan and Original Equipment Manufacturer (OEM) manuals. Responsible crew members must sign off on these records, ensuring traceability and crew accountability. This step isn’t just regulatory housekeeping—it aligns ballast water maintenance with how other onboard systems are already tracked, from engines to emissions. It’s a logical, overdue move toward consistency across compliance. Paper or digital: The format dilemma While the BWRB can still be maintained on paper or electronically, the burden of new structured data fields and stricter reporting timelines will be felt most by those still tied to manual systems. Each additional layer of documentation increases the chance of human error—and with nearly 6 in 10 compliance failures already stemming from admin issues, that’s a risk many operators can’t afford. This is where digital solutions can offer real relief. At NAPA, we’ve already implemented the latest IMO guidelines into our electronic logbook, so crews can comply with MEPC.369(80) requirements out of the box. With ready-made entry templates and smart input validation, data entry is quick, accurate, and audit-ready. NAPA implemented the latest IMO guidelines into an electronic logbook. Better still, once updated, operators can apply for the BWM Convention Electronic Record Book Declaration from their flag—ensuring that compliance is recognised internationally under MEPC.372(80). Less admin, more assurance Electronic logbooks don’t just streamline compliance—they enable better decision-making. When connected to onboard systems, they automatically pull operational data into the BWRB, reducing manual work and error margins. This frees up the crew to focus on operations and safety, rather than paperwork. From a management perspective, real-time visibility into ballast operations and maintenance records helps shore teams stay ahead of inspections and identify potential compliance gaps early. One logbook, many regulations While ballast water is the focus today, it’s not the only regulation demanding attention While ballast water is the focus today, it’s not the only regulation demanding attention. At NAPA, we’ve designed our logbook to support a wide range of evolving compliance frameworks—including MARPOL, EU-ETS, EU-MRV, CII, and the Garbage Record Book. This unified approach removes silos, reduces duplicated effort, and gives operators a more holistic view of vessel performance and compliance. A smarter way forward With decarbonisation and environmental regulations shifting at breakneck pace, even the most experienced crews and fleet managers can struggle to stay up to date. That’s where technology has a crucial role to play—not to replace expertise, but to support it. At NAPA, we work closely with shipowners and operators to configure regulatory record book templates according to their fleet workflows and each vessel’s specific operational profile. This ensures accuracy, ease of use, and most importantly, continuous compliance—even as the rules keep changing. Because in today’s compliance landscape, staying ahead isn’t just about meeting the minimum. It’s about building systems that help you adapt, respond, and thrive. And that starts with getting the record-keeping and data management right.

Maritime communications came a long way before they could deliver the first Global Maritime Distress and Safety System (GMDSS). Still, it is fair to say that their forward march has only accelerated in the two-and-a-half decades since. Today, shipping companies rely on satellite connectivity to protect their vessels and people and enable the digitalisation, decarbonisation, and crew-welfare initiatives on which its successes rely. Low-Earth orbit (LEO) networks Against this background, the new generation of low-Earth orbit (LEO) networks has entered the maritime market to great fanfare and expectation from ship owners, and their excitement is justified: LEO satellite coverage has the potential to span the globe, providing exceptional reliability and speed even during long voyages in the most remote locations. This facilitates real-time communication and efficient coordination between vessels and onshore personnel, ultimately supporting more profitable and sustainable fleet operations. Level of connectivity Moral obligations and regulatory requirements aside, providing high-quality crew internet LEO’s introduction into the maritime sphere has been equally well received by seafarers, who stand to benefit from a level of connectivity that keeps them better connected to family and friends than ever before, and to richer entertainment options at sea. Moral obligations and regulatory requirements aside, providing high-quality crew internet represents a wise investment from a competitive standpoint, enhancing as it does an organisation’s ability to attract and retain the brightest talent. Another advantage to seafarers and their employers, LEO connectivity offers stable onboard access to non-leisure services including mental-health support, telemedicine, and online learning resources, helping to keep a crew happy, healthy, and up to speed with the evolving requirements of their job. Limitations For all the benefits of LEO networks, it is important to acknowledge their limitations. For instance, LEO’s promise of delivering worldwide coverage remains to be realised, with certain countries yet to authorise its use in their territorial waters. This means that, depending on the trading route, a ship may encounter multiple LEO-coverage blackspots during its voyage. Susceptible to interference Regardless of the network type being used, vessels still need to compress and throttle data Like many satellite technologies, LEO networks are also susceptible to interference from atmospheric conditions that can disrupt communications, while network congestion at hotspots and drop-out at satellite handover may present additional connectivity challenges. Regardless of the network type being used, vessels still need to compress and throttle data on certain occasions, such as while in port, but LEO networks currently cap utilisation and therefore limit connectivity and availability further. Crew and commercial use In addition, maritime organisations should consider whether their LEO system is for both crew and commercial use. For a vessel deploying LEO connectivity to cover crew and business communications simultaneously, even a terabyte of data is unlikely to go far. Divided among a crew of 25, it equates to 40 gigabytes per person, enough for 13 hours of HD streaming with nothing remaining for commercial requirements. The solution Maritime software including critical communications-based services will need to be compatible with LEO To ensure reliable and consistent connectivity, support enhanced GMDSS communications, and meet the bandwidth needs of all stakeholders, a vessel will require multiple satellite provisions. This means that maritime software including critical communications-based services will need to be compatible with both LEO and more traditional, low-bandwidth networks and be able to switch between connections automatically to ensure uninterrupted service. GTMailPlus GTMaritime’s GTMailPlus, for example, is compatible with all major network types, regardless of bandwidth. Developed with optimisation in the maritime environment in mind, it provides secure and efficient data transfers irrespective of the service or combination of services a shipowner or manager uses. If disruptions do occur, GTMailPlus resumes data transmission from the point of interruption. Risk of a cybersecurity breach There have already been several reported cases of ship owners falling victim to significant cyber incidents As crew freedoms on the Internet increase and more onboard devices are connected to the network, the risk of breaches to cybersecurity is also rising dramatically: effectively, the vessel becomes a larger attack surface. There have already been several reported cases of ship owners falling victim to significant cyber incidents having adopted LEO systems without taking the necessary security precautions. Robust, intelligent, and scalable network Given that ships transfer diverse types of data that often involve critical and sensitive information, the consequences of any breach of vessel operations, safety, and privacy can be severe. Here too, the GTMaritime portfolio is continuously evolving to ensure robust, intelligent, and scalable network protection for owners. AI-based next-gen anti-virus technology In addition to the enhanced security features included in all GTMaritime solutions, enables a holistic approach In the latest partnership with CrowdStrike, GTMaritime’s cyber-security offering combines AI-based next-generation anti-virus technology with end-point detection and response capabilities. This, in addition to the enhanced security features included in all GTMaritime solutions, enables a holistic approach to vessel security. Conclusion LEO networks undoubtedly present a considerable opportunity for the maritime industry and have the power to transform connectivity at sea. However, there are several factors to consider before adopting an LEO system and regardless of advances in technology, optimised solutions for critical communications, security, and data transfer remain essential.

Harbour insights

FuelEU Maritime came into effect on Jan. 1, 2025. It is part of the European Union’s Fit for 55 package and applies to commercial vessels of 5000GT (gross tonnage) and over used for the transport of cargo or passengers and calling at EU ports. Vessels are required to achieve a greenhouse gas (GHG) intensity of energy below a particular level. That level reduces over time and by 2050 the reduction target is 80% compared to 2020 reference levels. GHG intensity of energy obligations “FuelEU is designed to reduce the energy intensity of fuel used by ships and to drive the uptake of alternative fuels,” says Helen Barden, Director – External Affairs, NorthStandard, an insurer providing Protection and Indemnity (P&I) coverage. She adds, “For vessels that do not meet the GHG intensity of energy obligations, there are options for borrowing compliance from future years, pooling the vessel with better-performing vessel(s) or paying a penalty. For container and passenger ships there are requirements to connect to shore power from 2030.” Ship’s energy intensity FuelEU Maritime measures a ship’s energy intensity over a full reporting year on a well-to-wake basis FuelEU Maritime measures a ship’s energy intensity over a full reporting year on a well-to-wake basis. Well-to-wake therefore includes emissions from well (i.e., production) to tank (i.e., on the ship) plus tank-to-wake (i.e., it propels the ship). Assessing the energy intensity on a well-to-wake basis, rather than simply tank-to-wake, provides a better reflection of the emissions created during the lifecycle of a marine fuel. Wind-assisted propulsion systems “There are many energy efficiency technologies on the market, such as improving the efficiency of hull coatings, or making changes to the bulbous bow or propeller, but these go to improving the energy efficiency and are not included in the calculation to improve the energy intensity of the fuel used,” says Helen Barden. However, wind-assisted propulsion systems receive a Wind Reward Factor in the regulation, which means this technology does impact the vessel’s GHG intensity rating. Of course, zero or near zero fuels and renewable fuels of non-biological origin also go to the GHG intensity rating. Compliance of FuelEU The compliance of FuelEU rests with the DOC holder under the ISM code While the compliance of FuelEU rests with the Document of Compliance (DOC) holder under the International Safety Management (ISM) code, which may well be the ship manager rather than the registered owner, the ship manager will in reality want to pass the liability for compliance on to the ship owner, says Barden. The ship owner (and indeed possibly together with the charterer depending on the length of the charter party and nature of the commercial relationship) will need to produce a strategy for compliance with FuelEU Maritime given there are different options for compliance available, she says. Lower energy intensity fuels and energy sources Helen Barden says payment of the penalty should be the last resort. “Not only is this likely to be the most expensive option, but it also comes with implications for future years in the form of a multiplication factor,” she states. Helen Barden adds, “Whether pooling, using lower energy intensity fuels and energy sources, or borrowing compliance from future years as part of a strategy will depend on many variables and, therefore, a compliance strategy should be given considered thought. This will also impact on the terms of any contracts.” Respect of GHG energy intensity Financial penalties apply to any company that does not meet its compliance obligations There are pooling platforms on the market now, such as Bettersea, which is currently offered to NorthStandard members at a preferential rate. Financial penalties apply to any company that does not meet its compliance obligations in respect of GHG energy intensity. Failing to comply for two or more consecutive years will see the penalty factor multiplied, while failure to present a FuelEU Maritime certificate of compliance for two or more consecutive reporting periods could result in a ship being banned from EU ports. Vessel’s compliance balance If a vessel exceeds the compliance requirements and so has a positive compliance balance for a reporting period, this “surplus” can either be pooled or can be banked for compliance in future years. Parties will need to consider whether charterers will get the full benefit of compliance pooling, banking or borrowing, and how this will work where the charter party does not cover the full reporting year. A vessel’s compliance balance may not be included in more than one pool in the same reporting period, but the vessel may be switched to a different pool in a different reporting period. Responsibility for FuelEU compliance rests The ultimate responsibility for FuelEU compliance rests with the ISM company The ultimate responsibility for FuelEU compliance rests with the ISM company (i.e., the Document of Compliance holder under the ISM Code) and, therefore, careful consideration must be given to the contractual implications of FuelEU Maritime. The Baltic and International Maritime Council (BIMCO) has produced a FuelEU Maritime Clause for Time Charter Parties and a Clause for ship management agreements, too, to help support owners, charterers, and ship managers in this regard. However, these clauses cannot just be inserted without consideration. As mentioned earlier, things like the compliance strategy should be thought through as this will impact the wording used in the clause, says Barden. Advice on the BIMCO clause “The BIMCO clauses are certainly a helpful starting point, but ship managers, ship owners and charterers must consider the terms carefully and, if necessary, make amendments,” says Helen Barden. She adds, “We have been assisting a number of our members with advice on the BIMCO clause in their particular circumstances, and indeed non-industry clauses that have also been proposed.”

Traditionally, bulk cargo unloading has faced challenges around operational efficiency, safety risks, environmental impacts, and high operational costs. Rough discharges, equipment wear, vibration damage, and limited weather operating windows have all constrained vessel utilisation and performance. Moreover, older unloading systems are energy-intensive and labour-dependent, increasing both costs and environmental footprint. Cargo unloading systems Many bulk cargo unloading systems depend on steep slope angles, which limit the types of materials that can be carried efficiently. MacGregor’s GravityVibe directly addresses this factor by allowing efficient discharge with significantly lower slope angles, thus broadening the range of cargo that can be handled. Many bulk cargo unloading systems depend on steep slope angles. Ship structures and unloading equipment “GravityVibe reduces reliance on gravity alone by augmenting the flow with controlled vibration,” says Mikael Hägglund, Senior Manager, Cranes at MacGregor. “This approach improves operational efficiency, enhances safety through more predictable material flow, and reduces wear on ship structures and unloading equipment.” Challenges of space utilisation and cargo versatility MacGregor is a provider of cargo and load handling solutions to maximise efficiency Additionally, the GravityVibe system will, in most cases, require only one hold conveyor and no cross conveyor in the hold, making the operations both cost-effective and sustainable, says Hägglund. MacGregor, based in Helsinki, Finland, is a provider of cargo and load handling solutions to maximise efficiency of maritime operations. As an augmented gravity self-unloading system, GravityVibe enhances cargo flow using vibration, enabling bulk materials to be discharged efficiently at lower slope angles (15–20 degrees). It reduces material blockages and optimises discharge without requiring steep holds, addressing the challenges of space utilisation and cargo versatility. Mechanical strain on vessel structures The system lessens mechanical strain on vessel structures, and supports safer, smoother, and more efficient operations across different cargo types. “Using lower slope angles allows ships to maximise cargo hold volume and transport a wider variety of bulk materials, including those that would not flow well with conventional systems,” says Hägglund. “It improves operational flexibility.” Integrity of the vessel Vessels benefit from a more compact and efficient hold design, optimising stability and construction Structurally, vessels benefit from a more compact and efficient hold design, optimising stability and potentially lowering construction and maintenance costs, adds Hägglund. “Managing vibration and sound levels is critical for maintaining the structural integrity of the vessel and ensuring crew safety and comfort,” he says. “Excessive vibration can lead to accelerated wear on ship components and fatigue damage over time.” GravityVibe’s design GravityVibe’s design ensures that both vibration and sound levels stay well below class-defined thresholds, preserving vessel longevity and reducing long-term maintenance and repair costs. Bulk cargoes have widely varying properties such as particle size, cohesiveness, moisture content, and chemical reactivity, all of which impact flow behaviour. Sticky, wet, or coarse materials require different unloading strategies to avoid blockages, segregation, or structural strain. Bulk cargoes have widely varying properties like particle size and cohesiveness. Broader spectrum of cargo types Key elements to achieve automation include fine-tuning self-optimisation algorithms GravityVibe’s vibration-driven approach adapts to these material differences, maintaining consistent discharge rates and ensuring operational reliability across a broader spectrum of cargo types without manual intervention or excessive mechanical modification, says Hägglund. More automated systems are on the horizon. Fully automated discharge is rapidly approaching reality, thanks to intelligent unloading systems like GravityVibe. Key remaining elements to achieve automation include fine-tuning self-optimisation algorithms, integrating predictive maintenance solutions, and standardising automation interfaces between vessels and ports. GravityVibe features MacGregor is actively working to refine onboard software, improve material recognition capabilities, and enhance real-time adjustment features. Wider industry adoption and regulatory frameworks are also crucial for achieving fully autonomous and seamless bulk unloading. GravityVibe features a built-in self-optimisation system that uses sensors to monitor material flow characteristics during discharge. Based on live data, it automatically adjusts vibration frequency and intensity to match the properties of each specific cargo, ensuring optimal unloading performance without manual recalibration. MacGregor is working to refine onboard software and improve material recognition. GravityVibe’s performance GravityVibe’s performance has been verified through a combination of laboratory studies MacGregor is fine-tuning this system by gathering real-world data from full-scale test rigs, analysing operational performance across various cargo types, and incorporating feedback loops to continually improve discharge efficiency and system responsiveness. Real-world validation is essential to prove that unloading systems perform reliably under operational conditions. GravityVibe’s performance has been verified through a combination of laboratory studies and full-scale rig testing. In-house tests and studies For example, validation by bulk solids researcher TUNRA showed efficient unloading across diverse materials such as wood chips, manufacturing sand, and gravel. In-house tests and studies with external specialists like KTH have confirmed low vibration levels, consistent discharge flow, and high operational reliability, providing strong evidence for commercial deployment. TUNRA showed efficient unloading across diverse materials such as sand. GravityVibe’s system design GravityVibe’s system design is based on long-lasting parts and improved cargo flow High maintenance requirements traditionally have led to significant downtime and increased operational costs. GravityVibe’s system design is based on long-lasting components and improved cargo flow that reduce risks for failures and needed service, thereby lowering maintenance costs/needs. “With real-time monitoring and smart diagnostics, potential issues can be detected and addressed before they escalate, minimising service interruptions,” says Hägglund. “This proactive approach enhances equipment availability and ensures better operational continuity for vessel operators.” MacGregor GravityVibe system When unloading standard bulk carriers, there is a need to clean the holds with manpower and external machines as the port cranes or the vessel cranes will not be able to empty the holds. The weather could also be a factor for delay in cases where the cargo is sensitive to water. For the MacGregor GravityVibe system, all material will be removed from the hold without any extra efforts. GravityVibe demonstrates that with intelligent use of vibration and lower slope angles can achieve the same — or even better — results. This approach not only enables broader cargo flexibility but also reduces structural stress, energy consumption, and environmental footprint.

Ammonia is gaining traction as a future fuel in the maritime industry, primarily due to its potential to significantly reduce greenhouse gas emissions. A key driver for ammonia's interest is that it can be carbon-free when combusted, which aligns with the maritime industry's increasing pressure to meet emissions regulations. However, most ammonia production currently relies on fossil fuels. Transitioning to "green ammonia" production is crucial for sustainability. If "green ammonia" is produced using renewable energy sources, it offers a pathway to near-zero emissions shipping. Safety measures and regulations Ammonia’s volumetric energy density – higher than hydrogen – makes it more practical for onboard storage. However, ammonia is toxic, which requires stringent safety measures and regulations for handling and storage. The combustion of ammonia can produce nitrous oxide (N2O), a potent greenhouse gas. Therefore, mitigation technologies are needed. Building the necessary infrastructure for ammonia bunkering and supply will be a significant undertaking. Developing guidelines for safe use Ammonia is poised to play a significant role in the maritime industry's transition to a future The International Maritime Organization (IMO) is developing guidelines for the safe use of ammonia as a marine fuel. Increasing numbers of companies are investing in the development of ammonia-fueled vessels and technologies. European Union (EU) legislation, such as the EU Emissions Trading System (ETS) and the FuelEU initiative to support decarbonisation, are pushing the maritime industry towards the use of alternative fuels, which is increasing the potential of ammonia. While challenges remain, ammonia is poised to play a significant role in the maritime industry's transition to a more sustainable future. Ongoing research and development Ongoing research and development are focused on improving safety, reducing emissions, and scaling up production. In essence, ammonia offers a promising pathway for the maritime industry to reduce its carbon footprint, but its widespread adoption depends on overcoming technical and logistical challenges. Working toward the future of ammonia Progress is already happening as the maritime industry works toward a future that includes the use of ammonia as a fuel. For example, one project underway aims to be a pioneer in establishing a comprehensive and competitive supply chain to provide clean ammonia ship-to-ship bunkering in the U.S. West Coast. Progress is already occurring as the maritime industry works toward a future A feasibility study is being conducted at the Port of Oakland, Benicia, and nearby major ports on the U.S. West Coast. A Memorandum of Understanding (MOU) between American Bureau of Shipping, CALAMCO, Fleet Management Limited, Sumitomo Corp. and TOTE Services LLC is jointly conducting the feasibility study. "We are proud to share our industry-pioneering expertise in ammonia as a marine fuel to support this study on the U.S. West Coast,” said Panos Koutsourakis, Vice President of Global Sustainability at the American Bureau of Shipping. “Our expertise in developing safety guidelines will support the consortium to address the ammonia-specific set of safety and technology challenges.” More global ammonia developments In another development, three LPG/ammonia carrier ships have been ordered at the South Korean shipyard HD Hyundai Heavy Industries (HD HHI). Danish investment fund European Maritime Finance (EMF) and international shipping company Atlas Maritime have confirmed the order. HD HHI’s parent company, HD Korea Shipbuilding & Offshore Engineering (HD KSOE), revealed the order for $372 million in March 2024. The three 88,000 cubic-metre LPG dual-fuel carriers, capable of carrying and running on ammonia, are scheduled for delivery in December 2027. The vessels will be named EMF Viking I, II, and III. Also, Lloyd’s Register (LR) and Guangzhou Shipyard International have signed a joint development project to design the world’s largest very large ammonia carrier (VLAC). The design of the 100,000-cubic-metre vessel has been assessed in line with LR’s Structural Design Assessment and prescriptive analysis. The gas carrier will have an independent IMO Type B tank for safe carriage of the chemical. Zero-emissions operations The cargo ship, which will be 7,800 dwt, is designed to transport timber from Norway to Europe “As major economies look to co-fire ammonia in their coal power stations to reduce the CO2 footprint of their national energy mix, shipping will play a key role in distributing clean hydrogen-based commodities such as ammonia, thereby supporting nations to meet their Paris Agreement commitments," says LR's Chief Executive Nick Brown. Furthermore, a partnership of companies from Norway has ordered a pioneering short-sea cargo ship that will advance the industry’s ability to provide zero-emissions operations. The cargo ship, which will be 7,800 dwt, is designed to transport timber from Norway to Europe and will be the first to operate on ammonia and electricity. Amogy’s ammonia-to-electrical power system A start-up company focusing on ammonia-to-power technology, Amogy, demonstrated the first tugboat powered by its cracking technology just short of the fourth anniversary of the company’s launch. The trip of a 67-year-old tug along a tributary of New York State’s Hudson River is part of the company’s works to develop and commercialise its technology to decarbonise the most difficult industries. Amogy’s ammonia-to-electrical power system splits, or “cracks,” liquid ammonia into its base elements of hydrogen and nitrogen. The hydrogen is then funnelled into a fuel cell, generating the power for the vessel. Research points to the risks of ammonia The chemical, made of hydrogen and nitrogen, can also be burned as a zero-carbon fuel Today and in the future, ammonia, a main component of many fertilisers, can play a key role in a carbon-free fuel system as a convenient way to transport and store clean hydrogen. The chemical, made of hydrogen and nitrogen, can also be burned as a zero-carbon fuel. However, new research led by Princeton University scientists illustrates that even though it may not be a source of carbon pollution, ammonia's widespread use in the energy sector could pose a grave risk to the nitrogen cycle and climate without proper engineering precautions. Use of ammonia U.S. National Science Foundation (NSF)-supported research found that a mismanaged ammonia economy could ramp up emissions of nitrous oxide, a long-lived greenhouse gas around 300 times more potent than carbon dioxide and a major contributor to the thinning of the stratospheric ozone layer. The use of ammonia could lead to substantial emissions of nitrogen oxides, a class of pollutants that contribute to the formation of smog and acid rain. And it could directly leak fugitive ammonia emissions into the environment, forming air pollutants, impacting water quality and stressing ecosystems by disturbing the global nitrogen cycle. Negative impacts of an ammonia economy The researchers found that the potential negative impacts of an ammonia economy "We have great hope that ingenuity and engineering can help reduce our use of carbon-based energy sources," said Richard Yuretich, a program director in NSF's Division of Earth Sciences. "But caution is advised because of unintended environmental spillover effects that may result from new technology." The researchers found that the potential negative impacts of an ammonia economy may be minimised with proactive engineering practices, but the possibility of risks should not be taken lightly. Addressing an inconvenient reality As interest in hydrogen as a zero-carbon fuel has grown, so too has an inconvenient reality: It is notoriously difficult to store and transport over long distances, requiring storage at either temperatures below -253 degrees Celsius or at pressures as high as 700 times atmospheric pressure. Ammonia, on the other hand, is much easier to liquify, transport and store, and capable of being moved around similarly to tanks of propane. Nonetheless, the cycle of nitrogen is delicately balanced in Earth's critical zone, and extensive research must be undertaken to investigate the repercussions of ammonia combustion and to develop new methods to minimise the risks. Challenges of ammonia as a maritime fuel Here's a breakdown of the key challenges of using ammonia for maritime fuel: Toxicity and Safety: For human health, ammonia is highly toxic, posing a serious risk to human health through inhalation or skin contact. This necessitates stringent safety protocols, advanced leak detection systems, and thorough crew training. Relating to the environment, leaks can also harm aquatic ecosystems, requiring robust containment and mitigation measures. Combustion Challenges: Ammonia's combustion characteristics are less favourable than traditional fuels, requiring modifications to engine design and potentially the use of pilot fuels. Emissions: Combustion can produce nitrogen oxides (NOx) and nitrous oxide (N2O), both of which are harmful pollutants. Mitigating these emissions is crucial. "Ammonia slip" is also a concern, in which unburnt ammonia is released. Infrastructure and Supply Chain: Establishing a global network of ammonia bunkering infrastructure is a massive undertaking, requiring significant investment and coordination. Scaling up "green ammonia" production, using renewable energy, is essential for its sustainability. This requires a robust and reliable supply chain. Storage: Ammonia has specific storage requirements, and onboard storage systems must be designed for safety and efficiency. International Standards Needed: Consistent and comprehensive international regulations and standards are needed for the safe handling, transportation, and use of ammonia as a marine fuel. While the IMO is developing Guidelines, complete and ratified rules are still needed. Economic challenges: "Green ammonia" is currently more expensive than traditional fuels, although costs are expected to decrease as production scales up. Significant investments are needed in research, development, and infrastructure to make ammonia a viable maritime fuel. Also, dedicated ammonia-fueled engines are still under heavy development, and do not have widespread availability. The path to commercialisation Overcoming the variety of technical and other obstacles will require collaboration among governments, industry stakeholders, and research institutions. The timeline for ammonia deployment in maritime applications is actively unfolding, with key milestones happening now and soon. 2025 marks the first trials of two-stroke, ammonia dual-fuel engines on oceangoing ships. Engine manufacturers like MAN Energy Solutions and WinGD are progressing with their engine development, with initial deliveries soon. These pilot projects are crucial for gathering real-world data and building confidence in ammonia as a marine fuel. Development of comprehensive regulations As the maritime industry faces, ammonia is hoped to play a growing role in the fuel mix Gradual commercialisation will follow in the late-2020s as the technology matures and the infrastructure develops. The focus will be on refining engine technology, improving safety protocols, and establishing bunkering facilities in key ports. Wider adoption will likely follow in the 2030s, depending on factors such as the cost of green ammonia, the development of comprehensive regulations, and the expansion of the global supply chain. As the maritime industry faces increasing pressure to decarbonise, ammonia is expected to play a growing role in the fuel mix. Future of maritime It's likely that a combination of ammonia and other alternative fuels and technologies will be used in the future of maritime. Alternatives include methanol, liquid natural gas (LNG), hydrogen, biofuels, electric propulsion, and even nuclear power. Ammonia is a strong contender, bit it faces stiff competition from other promising technologies. The maritime industry's transition to a sustainable future will likely involve a diverse mix of fuel solutions.

Case studies

Höegh Autoliners has revolutionised maritime transport with its Aurora Class vessels, marking significant progress toward sustainable deep-sea shipping. These Pure Car and Truck Carriers (PCTCs) are designed to be the largest and most environmentally friendly in their class. Notably, the final four ships in this 12-vessel series are set to operate on sustainable ammonia, a zero-carbon fuel, upon their delivery in 2027. Aurora Class vessels Aurora Class vessels are initially running on LNG with the flexibility to transition to ammonia and methanol The Aurora Class vessels are initially running on liquefied natural gas (LNG) with the flexibility to transition to ammonia and methanol as these fuels become more accessible. This adaptability is emphasised by the ships’ receipt of DNV’s ammonia- and methanol-ready notations, a first in the PCTC segment. The final four vessels will feature MAN Energy Solutions’ two-stroke engines capable of being fuelled by ammonia, positioning them as pioneers in zero-GHG emission maritime transport. TGE Marine’s expertise A key enabler of this technological leap is TGE Marine, whose advanced tank designs and fuel gas handling solutions are at the core of the vessels’ ammonia propulsion capabilities. TGE Marine’s expertise in designing and engineering maritime gas systems has made them a global pioneer in gas containment and fuel supply technologies. Their tanks are specifically developed to safely store ammonia in maritime conditions, while their fuel gas systems are among the most advanced in the industry ensuring reliable fuel management, safe operations, and seamless engine integration. These solutions exceed the stringent safety and performance standards required for ammonia as a marine fuel. New ammonia fuel supply system TGE Marine has already supplied tanks and fuel gas systems to the first eight Aurora class vessels TGE Marine has already supplied tanks and fuel gas systems to the first eight Aurora class vessels, and within the final four vessels, the fuel supply system is intended to handle ammonia fuel which allow for the vessels to be an engineering front runner in the industry. The new ammonia fuel supply system comes among others with a reliquefaction system, a gas combustion unit (GCU) and an ammonia release and mitigation systems (ARMS). Aspects of TGE Marine’s contribution The following expands on the specific aspects of TGE Marine’s contribution to the vessels: Fuel Supply System: The fuel supply system is streamlined to support the main engine operation in an optimum manner allowing a reliable and stable operation with ammonia as fuel. The design of the system is addressing the demand to increase ammonia integrity and to allow safe operation incl. maintenance. Key design features are the utilisation of sealless pumps, high integrity equipment and automation resp. remote operation. Boil-off Gas (BOG) Treatment: The heat ingress into the ammonia storage tank will lead to evapouration of ammonia. To keep the tank pressure within allowable limit the vapour, the BOG, is routed from the type-c tank’s vapour space to the BOG Treatment System. The BOG Treatment system consists of two fully independent methods to manage the tank pressure, i.e., the Reliquefaction System and the Gas Combustion Unit (GCU). Reliquefaction System: Onboard reliquefaction systems are engineered to recondense the ammonia vapour that results from heat ingress into the storage tanks and system operation. Gas Combustion Unit: As with all systems, TGE Marine also ensure that in an unlikely event that the reliquefaction system would fail, a secondary ‘back up’ system would kick in. The method chosen for this set up a gas combustion unit (GCU). This method burns the boil off gas, and this allows the tank temperature and tank pressure to remain within the limits. The gas combustion unit can support also the treatment of nitrogen ammonia mixtures and non-standard operations, such as gas-freeing of systems for maintenance preventing the release of ammonia to the atmosphere. Safety Systems: Key for operating a vessel with ammonia as fuel is the safe operation taking the toxicity of ammonia into consideration. TGE Marine has implemented safety systems and measures into the design of the system. Risk assessments accompany the design and execution of the project at every stage. Ammonia recovery: A key element of the safe operation is the handling of potential operational and emergency releases originating from the fuel supply system and engine purge operations. For this purpose, an ammonia recovery system is applied to reduce the ammonia quantities being routed to the ammonia release mitigation system. Ammonia Release Mitigation System: The ammonia release mitigation system developed by TGE Marine, is reducing the ammonia quantity released to the atmosphere and ensures that ammonia concentrations are below health and safety limits. Primary benefits of configuration To underline the benefits of the system, these following can be listed as primary benefits of using such configuration: Fuel Efficiency: By applying an efficient ammonia fuel supply system and ammonia engine Environmental Compliance: Minimising emissions of ammonia gas into the atmosphere reduces the vessel’s environmental footprint and helps comply with stringent emissions regulations Safety and Stability: The system ensures stable operation, reducing the risk to personnel and enhancing onboard safety Operational Flexibility: This technology supports extended voyages without fuel losses and allows better management of varying fuel demands during different operational profiles New standard for sustainability in maritime transport Beyond propulsion, the Aurora Class vessels incorporate several eco-friendly features, some include 1,500 square metres of solar panels and the capability to connect to electric shore power, enabling emissions-free port operations. With these advancements, Höegh Autoliners, together with key partners like TGE Marine, is not only reducing its carbon footprint but also setting a new standard for sustainability in maritime transport, steering the industry toward a greener future.

San Francisco-based maritime technology company - Sofar Ocean announces a partnership with the U.S. Naval Meteorology and Oceanography Command’s (CNMOC) Fleet Weather centres in Norfolk (FWC-N) and San Diego (FWC-SD). Wayfinder platform FWC-N and FWC-SD, the Navy’s two primary weather forecasting centres, are piloting Sofar’s Wayfinder platform to support the routing of naval vessels at sea. The FWCs are utilising Wayfinder to identify safe and efficient route options powered by real-time ocean weather data for Military Sealift Command (MSC) ships. Situational awareness Tim Janssen, Co-Dounder and CEO of Sofar, said, "Wayfinder will empower the Navy to enhance situational awareness at sea and leverage data-driven optimisation to continuously identify safe and efficient routing strategies." He adds, "Powered by our real-time ocean weather sensor network, Wayfinder will help the Navy scale its routing operations to support a heterogeneous fleet operating in conditions made more extreme by the effects of climate change." CRADA The platform displays real-time observational data from Sofar’s global network of Spotter buoys The Navy is evaluating Wayfinder under CNMOC and Sofar’s five-year Cooperative Research and Development Agreement (CRADA) signed in July 2023. Wayfinder reduces manual tasks for forecasters and routers by automatically generating a forecast along a vessel’s route. The platform displays real-time observational data from Sofar’s global network of Spotter buoys to reduce weather uncertainty for route optimisation, and predict unwanted vessel motions during a voyage. Real-time wave and weather observations The availability of accurate real-time wave and weather observations helps Captains and shoreside personnel validate forecast models and examine multiple route options more efficiently, streamlining a historically complex and arduous process. Lea Locke-Wynn, Undersea Warfare Technical Lead for CNMOC’s Future Capabilities Department, said, "A key focus area for the Naval Oceanography enterprise is fostering a culture of innovation through collaboration with our commercial partners." Vessel-specific guidance Lea Locke-Wynn adds, "Our ongoing CRADA with Sofar Ocean is a perfect example of how our partnerships can leverage the leading edge in industry to further Department of Defence operations." As the number of naval vessels at sea, including experimental and autonomous ships, continues to increase, forecasters and routers will have less time to spend manually producing vessel-specific guidance. Automated forecast-on-route guidance More efficient routing empowers FWC personnel to focus on challenging, mission-critical tasks Wayfinder helps fill this operational gap, enabling FWC-N and FWC-SD to more efficiently support a large fleet in real-time with automated forecast-on-route guidance. More efficient routing empowers FWC personnel to focus on challenging, mission-critical tasks that require their unique expertise. Streamlined decisions Captain Erin Ceschini, Commanding Officer, FWC-SD, stated, "By using Wayfinder, we’re able to better visualise our ships’ routes, and make safer and more streamlined decisions on route, speed, and heading." Captain Erin Ceschini adds, "Wayfinder has the potential to be a critical component of our day-to-day operations and a key driver of safe routing as we contend with an increasingly unpredictable weather landscape."

Strengthening trade relations and promoting collaboration between Valenciaport and China. This is the objective with which the Port Authority of València has traveled to China to participate in the 8th edition of the Maritime Silk Road Port International Cooperation Forum 2024, held from June 26 to 28, 2024 in Ningbo (China). The value proposition of the Valencian enclosure as a green, intelligent and innovative HUB of the Mediterranean has been the common thread of the presentation of the PAV in this forum. Advantages of Valenciaport as a strategic port Mar Chao has also described the strategic importance of Valenciaport for the Chinese market During the event, Mar Chao, President of the PAV, had the opportunity to present the competitive advantages of Valenciaport as a strategic port in the center of the Mediterranean (through which 40% of Spanish import/export is channeled) at the service of the business fabric of its area of influence and a link in the logistics chain. Mar Chao has also described the strategic importance of Valenciaport for the Chinese market as a key point of direct connection with Europe that promotes a green growth, market-oriented, with maximum efficiency in services and a complete logistic and multimodal integration. Commercial capacity of Valenciaport During her conference, the President also highlighted the commercial capacity of Valenciaport, with an area of influence of more than 2,000 kilometres that maintains a direct relationship with the main international ports. Cristina Rodríguez, Head of Containers of Valenciaport, accompanies Chao in the forum. Both have held business meetings with Asian companies and institutions, including the new president of the Port of Ningbo, Tao Chengbo. In the framework of this meeting, the representatives of Valenciaport and the Port of Ningbo have signed a memorandum of understanding (MOU) with the aim of strengthening their commercial collaboration. Silk Road Port and Maritime Cooperation Forum The Silk Road Port and Maritime Cooperation Forum of Ningbo (China) in which Valenciaport participates is a platform for open exchange and mutual learning in port development and maritime transport, within the framework of the Belt and Road Initiative. From a respect for the uniqueness of each participating port, the Forum is seen as a tool to foster collaboration in various fields to build bridges between supply and demand in business, investment, technology, talent, information, ports and cultural exchange.

GEM elettronica is proud to announce the conclusion of a strategic project to strengthen Lithuania’s defense capabilities, during which cutting-edge surveillance radars with airspace monitoring function were installed on four patrol ships of the Lithuanian Navy. The contract was executed successfully and within the agreed-upon timelines, thanks to the collaboration between the Italian defence companies Leonardo and GEM elettronica. Advanced radar system The heart of the system is the Columbus MK2 3D multi-mission radar developed and produced in house by GEM Elettronica, specially designed for coastal surveillance and naval applications, made with the latest technologies, which guarantee high detection performances for search and tracking of small and fast targets at both air and sea surface space, high reliability and availability with low maintenance and life cycle costs. It is a compact and lightweight advanced radar system for short- and medium-range detection performing all the functions of surveillance, self-defence, IFF capabilities and weapon designation. The new radar systems were installed on the Lithuanian Flyvefisken (Standard Flex 300) class offshore patrol vessels (OPVs) Žemaitis (P11), Dzūkas (P12), Aukštaitis (P14) and Sėlis (P15). Working effectively together The main role of the new equipment is to ensure the safety of ships when navigating in narrow passages The main role of the new equipment is to ensure the safety of ships when navigating in narrow passages (e.g., straits, port channels) and in the open sea, as well as in search and rescue missions. The systems will allow objects to be detected up to 100 kilometers away. The Commander of the Lithuanian Naval Forces Sea, Captain Giedrius Premeneckas underlined: “The successful implementation of this project represents a significant step in strengthening the capabilities of the Navy’s patrol vessels and significantly increasing our ability to carry out assigned tasks and work effectively together with NATO allies.” The President of GEM elettronica Ing. Antonio Bontempi answered “We are delighted to have successfully contributed to the realization of this strategic project. We are also proud of what achieved by our R&D and Production teams who worked together with passion and tenacity to ensure the project was achieved within the expected timescales.”