Allweiler Marine Pumps (Auxiliary) (14)

Browse Marine Pumps (Auxiliary)

Pump (auxiliary) products updated recently

Pumps (auxiliary) - Expert commentary

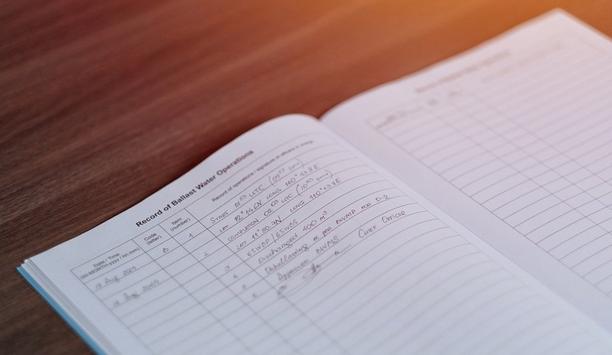

When the Ballast Water Management (BWM) Convention came into force in 2004, it was in response to a crisis we couldn’t afford to ignore—one where invasive aquatic speci...

Aiming to establish minimum requirements for the cyber-resilience of newbuild vessels and their connected systems, IACS unified requirements (URs) E26 and E27 provide a new benchma...

Latest Allweiler GmbH news

Allweiler launches the next-generation AEB-DE progressing cavity pump series of four pump sizes that share one installation footprint and are capable of bi-directional flow. Combi...

Allweiler, a business unit of CIRCOR, will exhibit at the Pumps & Valves trade fair in Dortmund, Germany February 12th and 13th 2020 (Hall 6, Booth R19-6). Highlights of their...

CIRCOR has launched the Allweiler SNA™ series of customisable three-screw lube oil pumps for diverse API 676/682 applications. The Allweiler SNA series allows for customised...

Trending topic articles

ClassNK has released 'ClassNK Technical Journal No.11 2025 (Ⅰ)'. This issue features the title 'Latest Technological Trends for Protection of the Marine Environment', providing the particularly well-r...

RAD Propulsion, a globally renowned innovator in electric marine propulsion systems, announced the expansion of its international dealer network with new strategic partnerships in the Netherlands, Ind...

As maritime companies digitise, decarbonise, and expand across continents, standing out in the market has never been more challenging. Customers expect clarity. Talent is scarce. And lead generation t...

Watson Farley & Williams advised ING Bank N.V., Singapore Branch—acting as arranger, lender and facility and security agent — on a term loan facility provided to Tank Container Investm...

LOOKOUT, the AI pioneer in marine safety, launched enhanced benefits to marine professionals through its preferred dealer and installer programme. The new resources help LOOKOUT dealers and installer...

A new advanced simulation suite supplied by technology group Wärtsilä for the Akademi Laut Malaysia (ALAM) maritime training institute was inaugurated on 17 July 2025. ALAM is the training a...

Alfa Laval announces that Martijn Bergink has been appointed President of the Marine Division, effective 1 September 2025. This is in addition to his current roles as President of Business Unit Pumpi...

Hefring Marine, the pioneer in intelligent marine analytics, announces the launch of its latest innovation: the Impact Report, a powerful new feature that delivers unprecedented visibility into vessel...

Econowind has received a repeat order from Terntank for the installation of eight VentoFoil units on two additional methanol-ready hybrid tankers. Following the initial order in May 2023 for three n...

Following the announcement by the Department for Transport (DfT) of a sixth round of the UK SHORE ‘Clean Maritime Demonstration Competition’ earlier this year, the winners have now been an...

2M Logistics Holding B.V. (NL) and the internationally operating Gallozzi Group (Italy) have entered into a strategic partnership. As business partners, both parties will collaborate closely on comme...

ClassNK has granted its Innovation Endorsement for Products & Solutions to the maritime cybersecurity support solution, ‘CYTUR-MCTI’ developed by CYTUR and its partner company - Rakute...

Watson Farley & Williams ("WFW") advised Pacific Basin Shipping ("Pacific Basin") on a US$250m sustainability-linked seven-year senior secured committed revolving credit facility. The facilit...

Alva Industries (Alva), a manufacturer of frameless motors and owner and creator of FiberPrinting technology, has announced the publication of a series of new white papers on FiberPrinted motors for h...

DNV has awarded a General Approval for Ship Application (GASA) certificate to Mitsui O.S.K. Lines, Ltd., (MOL), MISC Berhad (MISC), PETRONAS CCS Ventures Sdn. Bhd. (PCCSV), and Shanghai Merchant Ship...

ClassNK has released 'ClassNK Technical Journal No.11 2025 (Ⅰ)'. This issue features the title 'Latest Technological Trends for Protection of the Marine Environment', providing the particularly well-r...

RAD Propulsion, a globally renowned innovator in electric marine propulsion systems, announced the expansion of its international dealer network with new strategic partnerships in the Netherlands, Ind...

As maritime companies digitise, decarbonise, and expand across continents, standing out in the market has never been more challenging. Customers expect clarity. Talent is scarce. And lead generation t...

Watson Farley & Williams advised ING Bank N.V., Singapore Branch—acting as arranger, lender and facility and security agent — on a term loan facility provided to Tank Container Investm...

LOOKOUT, the AI pioneer in marine safety, launched enhanced benefits to marine professionals through its preferred dealer and installer programme. The new resources help LOOKOUT dealers and installer...

A new advanced simulation suite supplied by technology group Wärtsilä for the Akademi Laut Malaysia (ALAM) maritime training institute was inaugurated on 17 July 2025. ALAM is the training a...

Alfa Laval announces that Martijn Bergink has been appointed President of the Marine Division, effective 1 September 2025. This is in addition to his current roles as President of Business Unit Pumpi...

Hefring Marine, the pioneer in intelligent marine analytics, announces the launch of its latest innovation: the Impact Report, a powerful new feature that delivers unprecedented visibility into vessel...

Econowind has received a repeat order from Terntank for the installation of eight VentoFoil units on two additional methanol-ready hybrid tankers. Following the initial order in May 2023 for three n...

Following the announcement by the Department for Transport (DfT) of a sixth round of the UK SHORE ‘Clean Maritime Demonstration Competition’ earlier this year, the winners have now been an...

2M Logistics Holding B.V. (NL) and the internationally operating Gallozzi Group (Italy) have entered into a strategic partnership. As business partners, both parties will collaborate closely on comme...

ClassNK has granted its Innovation Endorsement for Products & Solutions to the maritime cybersecurity support solution, ‘CYTUR-MCTI’ developed by CYTUR and its partner company - Rakute...

Watson Farley & Williams ("WFW") advised Pacific Basin Shipping ("Pacific Basin") on a US$250m sustainability-linked seven-year senior secured committed revolving credit facility. The facilit...

Alva Industries (Alva), a manufacturer of frameless motors and owner and creator of FiberPrinting technology, has announced the publication of a series of new white papers on FiberPrinted motors for h...

DNV has awarded a General Approval for Ship Application (GASA) certificate to Mitsui O.S.K. Lines, Ltd., (MOL), MISC Berhad (MISC), PETRONAS CCS Ventures Sdn. Bhd. (PCCSV), and Shanghai Merchant Ship...

ClassNK has released 'ClassNK Technical Journal No.11 2025 (Ⅰ)'. This issue features the title 'Latest Technological Trends for Protection of the Marine Environment', providing the particularly well-r...