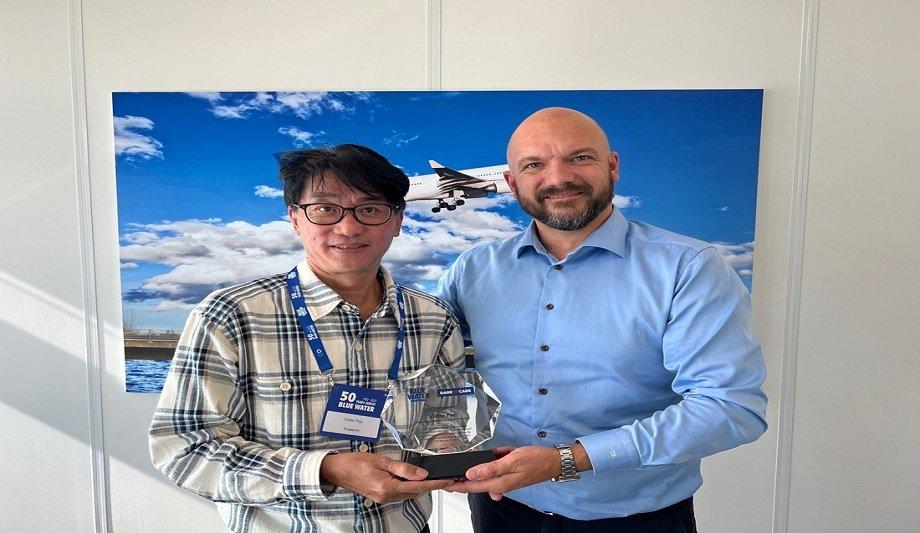

A Safety Award was presented by Thomas Bek, COO of Energy, Ports, and Projects, Blue Water recently.

It was awarded to Victor Pay, Transport & Field Operations Manager from the Technical Engineering Department, Blue Water Singapore for his remarkable excellence towards HSSEQ (Health, Safety, Security, Environment & Quality) stopping the job before it was handed to Blue Water’s scope of work.

Factory operations

Victor Pay was supervising a lifting operation remotely from Singapore. Due to COVID-19 restrictions, he was unable to be on site. Instead, third-party suppliers and barge operators provided live pictures of the operations in China.

The operation was for the factory to lift the cargo and land it onto a barge whereby Blue Water was to take over the transport.

Unsafe operation

He called the factory to explain the consequences and HSSEQ impact should the cargo drop on the barge

As the factory began the lifting operation, Victor observed the lift was unsafe from live pictures. He confronted the team and ordered them to stop the work immediately.

He called the factory and client to explain the consequences and HSSEQ impact should the cargo drop on the barge. It would lead to a catastrophic incident not only to the people around the area but also to massive damages to the cargo.

No cargo damage

The cargo was immediately grounded. Victor and the Blue Water Technical Engineering Department advised the team to add a spreader bar to support the lift, which would allow the lifting points to be reached on the cargo. The factory managed to quickly source suitable rigging gear.

“Although the lift was not under our scope of work, Victor clearly demonstrated that he dared to care for the health and safety of every person involved in the operations as well as the quality, ensuring no cargo damage should occur," says Thomas Bek.

Safest solution

"Working together with the client, factory, and our own team, he clearly displayed the Blue Water Way of creating safe operations.”

Victor explains, “When it comes to HSSEQ, it not only applies to our scope, but we must also ensure that HSSEQ is implemented at the beginning of every operation, and it is everyone’s responsibility that we stop the job when we see something unsafe and to not only find the best but also the safest solution.”