Energy saving

Alva Industries (Alva), a manufacturer of frameless motors and owner and creator of FiberPrinting technology, has announced the publication of a series of new white papers on FiberPrinted motors for high-performance applications. FiberPrinting technology is an advanced industrial winding technique used for the continuous winding of stator mats in slotless and ironless rotary and linear motors. This method maximises copper fill factor and enables precise customisation of size and stator...

DNV has awarded a General Approval for Ship Application (GASA) certificate to Mitsui O.S.K. Lines, Ltd., (MOL), MISC Berhad (MISC), PETRONAS CCS Ventures Sdn. Bhd. (PCCSV), and Shanghai Merchant Ship Design and Research Institute (SDARI), for their jointly developed 62,000 cubic metres (cbm) liquid carbon dioxide (LCO2) carrier design. This milestone builds upon an Approval in Principle (AiP) awarded by DNV in 2023 and highlights the growing role of Carbon Capture and Storage (CCS) in Asia&rsqu...

ClassNK has released 'ClassNK Technical Journal No.11 2025 (Ⅰ)'. This issue features the title 'Latest Technological Trends for Protection of the Marine Environment', providing the particularly well-received presentations on 'Underwater Noise from Ships' and 'Safe Decarbonisation’ from 'ClassNK R&D Forum 2025', which was attended by more than 200 participants. 'ClassNK Technical Journal', has been published to contribute to the advancement of technology and society through the outcome...

RAD Propulsion, a globally renowned innovator in electric marine propulsion systems, announced the expansion of its international dealer network with new strategic partnerships in the Netherlands, India and Japan. This move is a testament of RAD’s commitment to accelerate the global shift towards smart, clean, and efficient boating. Traditional combustion engine Energyboats will serve as RAD's official dealer in the Netherlands, focusing precisely on Benelux region Energyboats wi...

Alfa Laval announces that Martijn Bergink has been appointed President of the Marine Division, effective 1 September 2025. This is in addition to his current roles as President of Business Unit Pumping Systems in the Marine Division and Managing Director of Framo, an Alfa Laval-owned company. Martijn Bergink joined Alfa Laval in 1998 and, since then, he has held multiple senior leadership positions within the company, mostly in the Marine Division. Enhancing energy efficiency Martijn will co...

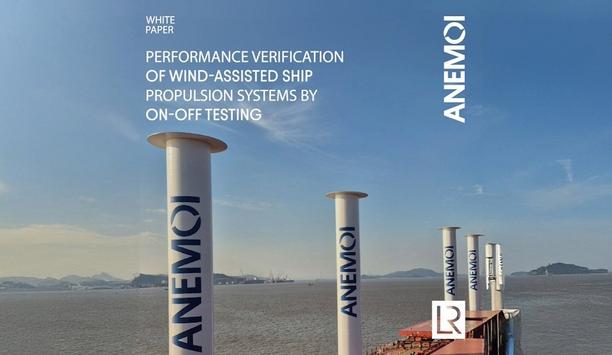

Anemoi Marine Technologies, a pioneer in wind-assisted propulsion technology, has developed an in-service performance verification process that reduces cost and complexity for operators while improving accuracy compared to existing practices. The new methodology aims to enable greater uptake of the climate-neutral, energy-saving advantages of wind-assisted propulsion. Wind-assisted propulsion system The data is used to calibrate predictions on forces generated by the rotor sail system The p...

News

With a new compact and versatile ship engine room pump design, Svanehøj aims to optimise onboard liquid handling. Because of its lower weight, fewer components, and just a single wear part, the new NCM pump will enhance efficiency, simplify system integration, and reduce operational complexity. For decades, Svanehøj has designed and manufactured a broad portfolio of engine room pumps for the marine, naval, and offshore sectors, continuing the legacy of the Hamworthy Pumps brand. Now, Svanehøj introduces a new monoblock pump design, the 'NCM Engine Room Pump' series, developed to enhance efficiency in operations onboard ships. Other engine room pumps NCM pump reduces weight by up to 15% compared to other engine room pumps on the market The NCM pump reduces weight by up to 15% compared to other engine room pumps on the market. Designed with fewer components, it is faster to assemble, disassemble, and maintain. A key innovation lies in its reduced wear parts. With only the mechanical seal subject to wear, the design ensures more consistent performance, fewer disruptions during operations, and a reduced need for spare parts. NCM pump series "With the NCM pump series, we’re introducing the marine market’s lightest, most efficient, and most compact engine room pump. By simplifying our design and product portfolio, we offer a range of engine room pumps with broader duty point spans that are highly competitive in terms of price, durability, and performance," says Morten Christian Larsen, Managing Director at Svanehoj Singapore. A fundamental shift in mindset The new NCM Engine Room Pump is a testament to Svanehøj’s strong tradition of marine pump innovation and its commitment to supporting the industry in powering a better future. The lightweight, compact design and minimal maintenance requirements reduce the pump’s overall environmental footprint while also improving working conditions for the crew onboard. Ship’s efficiency and overall operation "This is much more than just another pump design. It represents a fundamental shift in mindset and a complete relaunch, simplifying and strengthening our entire marine pump program," says Morten Christian Larsen, adding "Engine room pumps are critical to a ship’s efficiency and overall operation, and we firmly believe there is room in the market for a design that is fully optimised across the entire value chain, from manufacturing and installation to operation and maintenance." Once fully implemented, the new NCM Engine Room Pump series will enable Svanehøj to cover the full range of up to 1,500 m³ in capacity and up to 12 bar pressure with just 16 pump variants, significantly reducing complexity in engine room planning.

Dutch maritime solar innovator - Wattlab has delivered a solar energy system for HGK Shipping’s inland shipping cargo vessel - Blue Marlin. Representing a major technical milestone and step forward for sustainable inland shipping, the vessel’s 192 solar panels will provide power to both the onboard and propulsion systems, making the Blue Marlin the first inland shipping vessel in the world capable of hybrid sailing with solar power. Broad maritime experience HGK Shipping is a European inland waterway shipping company operating a fleet of 350 vessels HGK Shipping is a European inland waterway shipping company operating a fleet of 350 vessels. With annual freight figures in the region of 43 million tonnes, HGK Shipping is considered to be a pioneering player in European dry bulk, gas and chemical transport. Wattlab, which is also active in the seagoing shipping industry, brings broad maritime experience to this pioneering project. Wattlab has worked previously with HGK Shipping. In Q2 2024, HGK’s 135-metre-long dry cargo vessel MS Helios made headlines – and entered The Guinness Book of Records – for having the world’s largest solar panel installation on an inland shipping vessel. The MS Helios is equipped with 312 solar panels. Fully integrated system The solar energy systems of the Helios and the Blue Marlin differ in one critical aspect. Unlike the Helios, where solar energy was used exclusively for low-voltage onboard (hotel) systems, the Blue Marlin features a more advanced, fully integrated system capable of contributing power directly to the ship’s high-voltage electric propulsion. This, says Wattlab Co-Founder and COO, David Kester, is a technical milestone. “The Blue Marlin’s 192 solar panels are not only connected to the low-voltage onboard systems but also to the high-voltage propulsion network. This means that HGK Shipping can proudly state that they are the first inland shipping company to operate a vessel that uses solar power directly for propulsion.” Automated energy management Blue Marlin’s solar power system will operate in conjunction with four diesel generators Delivering up to 35 kilowatts under optimal conditions, the Blue Marlin’s solar power system will operate in conjunction with four diesel generators powering the electric propulsion system. This fully integrated setup enables ‘peak shaving’, where the combination of solar energy and batteries will prevent the need for activating an additional generator during high-demand periods. The system’s automated energy management will distribute electrical energy where and when it is required, increasing efficiency and reducing fuel consumption. “Furthermore, in situations where the ship is lightly loaded and travelling downstream, we anticipate that it may even sail using only solar power for limited periods — an unprecedented achievement in the inland shipping sector,” continues David Kester. Proud to pioneer "We have already reached a significant technical milestone with the construction of the Helios, which has had a noticeably positive impact. The Blue Marlin now goes one step further by also using solar energy for the power train. It makes another important contribution to making shipping, which is already a low-emission mode of transport, even more sustainable. We are excited to see how this innovative solution will prove itself in practical operation,” says Tim Gödde, Director Ship Management at HGK Ship Management Lux S.à r.l. He adds, “We are proud to pioneer the use of solar propulsion in inland shipping. The Blue Marlin demonstrates what’s possible when innovation meets engineering expertise.” Blue Marlin’s solar panels Installation of the Blue Marlin’s solar panels took place at De Gerlien van Tiem shipyard, with Wattlab Installation of the Blue Marlin’s solar panels took place at De Gerlien van Tiem shipyard, with Wattlab cooperating closely with Blommaert Aluminium and Van Tiem Electro. “We have been working with these partners for some time now – on multiple vessels – so have managed to really optimise the processes. The Blue Marlin is a new-build vessel; it took about one week for installation followed by a few days for commissioning,” said David Kester, adding “Considering a similar-sized retrofit project, we estimate that a shipowner would be looking at a downtime of no more than one week.” Scalable solar solutions for coastal and seagoing vessels This project also marks a broader evolution in maritime decarbonisation strategies. As regulatory pressure increases and fuel prices fluctuate, shipowners and operators are looking to diversify their energy mix. Wattlab’s scalable solar solutions are proving their viability not only on inland waterways, but also on coastal and seagoing vessels.

ABB has signed a 15-year service agreement with Royal Caribbean Group, a vacation industry pioneer with a global fleet of 67 ships across its five brands travelling to all seven continents, deepening the long-standing partnership to support the company’s ship performance goals. Covering 33 existing ships, the comprehensive agreement includes preventive maintenance and digital solutions to support and optimise propulsion operations, improve vessel safety, maximise fleet availability, and ensure fast turnaround times for planned Azipod® propulsion servicing. Financial terms were not disclosed. Installation of Azipod® propulsion “Our collaboration with Royal Caribbean Group spans nearly three decades, beginning with the installation of Azipod® propulsion on one of the world’s largest cruise ships at the time,” said Juha Koskela, President of ABB’s Marine & Ports division. “Since then, we’ve partnered on numerous pioneering projects. This service agreement marks an important milestone in our journey together and highlights the critical role of ABB’s solutions in modernising and maintaining the performance of one of the world’s most innovative cruise fleets.” Revolutionised marine transport Azipod® propulsion has revolutionised marine transport by delivering unparalleled gains for performance “This agreement exemplifies how a shared commitment to innovation can unlock new opportunities to improve progress toward ship performance goals,” said Palle Laursen, Royal Caribbean Group EVP and Head of Marine. From its creation over three decades ago to its pioneering position in shipping, Azipod® propulsion has revolutionised marine transport by delivering unparalleled gains for performance, efficiency, sustainability and reliability. Vessel manoeuverability and efficiency The gearless, steerable propulsion system, with the electric drive motor in a pod outside the ship’s hull, can rotate 360 degrees to increase vessel manoeuverability and efficiency, while cutting fuel consumption by up to 20 percent compared to conventional shaftline systems. Since the first installation on a cruise ship over 25 years ago, Azipod® technology has saved more than one million tons of fuel in the cruise segment alone.

Anemoi Marine Technologies, a pioneer in wind-assisted propulsion technology, has developed an in-service performance verification process that reduces cost and complexity for operators while improving accuracy compared to existing practices. The new methodology aims to enable greater uptake of the climate-neutral, energy-saving advantages of wind-assisted propulsion. Rotor sail system The data is used to calibrate predictions on forces generated by the rotor sail system The process, validated by the class society Lloyd’s Register Advisory, involves measuring vessel data when the wind-assisted propulsion system is turned on and off while encountering various conditions during regular operation. The data is used to calibrate predictions on forces generated by the rotor sail system and their impact on the vessel, which can be used to predict voyage fuel savings with high levels of confidence. Evaluation of wind-assisted propulsion systems Anemoi Technical Director, Luke McEwen, said: “With this paper, our aim is to bring greater transparency and consistency to the evaluation of wind-assisted propulsion systems. By describing our performance assessment methodology in detail, we hope to contribute meaningfully to the wider industry discussion and move closer to a standardised framework that enables clear, comparable results across all WAPS technologies." "While various approaches exist, a unified standard will be key to supporting informed decision-making and accelerating decarbonisation in shipping.” Challenges of applying traditional methodologies Lloyd’s Register Advisory confirmed that these benefits are accrued while improving the accuracy of overall fuel saving The methodology - published in the new whitepaper, Performance Verification Of Wind-Assisted Ship Propulsion Systems By On-Off Testing - can be used for all wind-assisted propulsion solutions, not just Anemoi’s Rotor Sails. It overcomes the challenges of applying traditional methodologies, such as ISO 19030, to WAPS assessment and eliminates costly operational changes, such as taking vessels off hire to perform dedicated WAPS sea trials, which are proposed by some standards. Lloyd’s Register Advisory confirmed that these benefits are accrued while improving the accuracy of overall fuel saving predictions. Wind-assisted propulsion verification Lloyd’s Register Advisory Ship Performance Manager, Dr. Santiago Suarez de la Fuente, added: “The current standards and guidelines around wind-assisted propulsion verification are relatively sparse, and an opportunity exists for a process that is robust, widely adopted, and transparent." "Anemoi’s methodology achieves this, allowing for predictions of performance to be applied to the entire range of conditions that a vessel and the system will encounter, without tests needing to be conducted in every condition.” Fuel savings of WAPS-equipped vessels The model developed using Anemoi’s process can be used throughout the life of the vessel to generate accurate fuel savings values, either in real time or on a voyage-by-voyage basis. It also enables the creation of advanced predictive tools that can estimate the power and fuel savings of WAPS-equipped vessels in a wide range of conditions. Net propulsion fuel savings Anemoi and Lloyd’s Register Advisory recently announced the results of the TR Lady Kamsarmax Anemoi and Lloyd’s Register Advisory recently announced the results of the TR Lady Kamsarmax, equipped with three of Anemoi’s 5m diameter, 24m tall Rotor Sails, assessed using the methodology outlined in the paper. Following a year-long, multi-voyage testing period, the robust approach demonstrated average net propulsion fuel savings of 9.1% and 7 tonnes of CO2e per sailing day. On-ship performance of technologies Commenting on the TR Lady’s performance testing, Chris Hughes, Decarbonisation Specialist at Cargill, the vessel’s charterer, said: “Building up an accurate understanding of the real-world, on-ship performance of technologies is a key piece in the wind assist propulsion puzzle. By combining the data from more than 167 rotor on/off tests that were conducted by the TR Lady, together with the independent verification from LR, Anemoi instilled confidence in the accuracy of their analysis." "We have already used the results of this study to fine-tune our weather routeing digital twins for TR Lady, and it will also help inform future decisions on deploying wind assist across our fleet.”

IMTRA, the globally renowned manufacturer and importer of quality solutions and products for the marine, energy and transportation markets, announced the introduction of the newest innovation in vessel pitch and roll control, Zipwake PRO. IMTRA is the exclusive distributor for Zipwake in the U.S. Zipwake PRO is the ultimate upgrade to Zipwake’s award-winning Dynamic Trim Control System. Zipwake Series S or E systems Zipwake PRO offers significant gains in version and precision for better acceleration Available for new installations and as an enhancement to existing Zipwake Series S or Series E systems, Zipwake PRO brings Active Pitch Control, improved Active Roll, Balanced and Coordinated turning and Wake Shaping functionality to boaters for perfect trim stability in any conditions. Featuring interceptors that move five times faster than legacy Zipwake systems, Zipwake PRO offers significant improvements in performance and precision for better acceleration, stability, comfort and lower fuel consumption. The system’s 0.3 second blade rate brings quicker adjustments, allowing the system to respond rapidly to changing conditions and optimise a boat’s handling. Next evolution in vessel control "We’re excited to introduce the next evolution in vessel control and comfort on the water with Zipwake PRO," said Jamie Simmons, IMTRA’s Zipwake Product Manager, adding "Zipwake’s Dynamic Trim Systems have been proven time and time again with over 60,000 installations globally." Jamie Simmons adds, "With features like Active Pitch Control and Active Roll and so much more, Zipwake PRO enhances the comfort of passengers and guests, while adding to the fun on the water in any application from cruising to wakeboarding and everything in between." Zipwake PRO features Balanced turn (coordinated turn) is now sharper, more precise and even faster with Zipwake PRO Zipwake PRO features Active Pitch, which allows continuous and rapid adjustments to the boat’s trim to maintain the pitch angle set by the user. Regardless of head seas, following seas, beam seas or changes in weight distribution, the system constantly works to keep the boat at the optimal running trim angle. Active Roll is another enhanced feature in the Zipwake PRO system. The ultra-fast interceptors ensure quicker, more precise corrections to rolling motions caused by changing conditions for greater passenger comfort. Balanced turn (coordinated turn) is now sharper, more precise and even faster with Zipwake PRO. System’s wake-shaping feature The system dynamically adjusts heeling angle, ensuring smoother, controlled turns at any speed. For those that enjoy tow and surf sports, the system’s wake-shaping feature provides easy control for fine-tuning wakes and creating ideal surfing conditions. In addition, Zipwake PRO has an adaptive interface that intelligently adjusts to display relevant information delivering a user-friendly experience for precise motion control. It also integrates with third-party MFDs. Local boatyards or marine equipment installers Distributed exclusively in the U.S. by IMTRA, Zipwake PRO is available in 25 different models, the widest range of interceptors available on the market today, with systems for boats from 20-feet to 100-feet in length. The Zipwake PRO system will be available this summer through local boatyards or marine equipment installers and backed by IMTRA’s renowned pre- and post-sales support.

The hull of the state-of-the-art DP3 cable-laying vessel - Nexans Electra arrived at Ulstein Verft on 5 July 2025. This marks the commencement of the outfitting and completion phase of the vessel. Upon completion in 2026, she will feature a split turntable on deck capable of holding up to 10,000 tonnes of cable, an under-deck turntable with a 3,500-tonne cable capacity, and a fibre optic tank with a 450-tonne capacity. Ulstein Verft and Nexans Ulstein Verft will also install the main parts, including the main generator set, power package The shipbuilding contract between Ulstein Verft and Nexans, a pure player in sustainable electrification and a pioneer in subsea cable systems, was signed in 2023. The hull has been under construction at the Crist yard, Poland. The hull will now be towed into the dock hall at Ulstein Verft, where outfitting, electrical work, insulation, and piping will commence. Ulstein Verft will also install the main components, including the main generator set, power package, deck machinery, winches, and topside equipment. Prepared for the future The Nexans Electra measures 155.2 metres in length and 31 metres in beam. She will be equipped for safe and efficient transport and installation of large volumes of HVDC and HVAC cable systems, as well as complex subsea construction tasks in deep waters. The vessel's built-in structural and system capacities, along with flexible design features, will allow easy adaptation to future customer needs. Large capacity and high capabilities Nexans Electra is based on the Nexans Aurora, which was delivered by Ulstein Verft in 2021 The Nexans Electra, designed by Skipsteknisk, is based on the Nexans Aurora, which was delivered by Ulstein Verft in 2021. She is specifically designed to transport and lay Nexans submarine products, including cable bundles, as well as perform recovery and repair of such products. The vessel can perform effectively in challenging weather conditions and boasts exceptional manoeuvrability and station-keeping characteristics. The incorporation of high-capacity shore power systems, an energy storage system, and biofuel compatibility ensures a reduced environmental footprint. Based on combined expertise The vessel has been developed through the combined experience of Nexans, Skipsteknisk, the Ulstein Verft yard, and NOV Remacut, each a pioneer in their respective fields. This collaboration has produced a Cable Lay Vessel for worldwide operations, covering the full range of shallow and deep subsea activities.

With a new compact and versatile ship engine room pump design, Svanehøj aims to optimise onboard liquid handling. Because of its lower weight, fewer components, and just a single wear part, the new NCM pump will enhance efficiency, simplify system integration, and reduce operational complexity. For decades, Svanehøj has designed and manufactured a broad portfolio of engine room pumps for the marine, naval, and offshore sectors, continuing the legacy of the Hamworthy Pumps brand. Now, Svanehøj introduces a new monoblock pump design, the 'NCM Engine Room Pump' series, developed to enhance efficiency in operations onboard ships. Other engine room pumps NCM pump reduces weight by up to 15% compared to other engine room pumps on the market The NCM pump reduces weight by up to 15% compared to other engine room pumps on the market. Designed with fewer components, it is faster to assemble, disassemble, and maintain. A key innovation lies in its reduced wear parts. With only the mechanical seal subject to wear, the design ensures more consistent performance, fewer disruptions during operations, and a reduced need for spare parts. NCM pump series "With the NCM pump series, we’re introducing the marine market’s lightest, most efficient, and most compact engine room pump. By simplifying our design and product portfolio, we offer a range of engine room pumps with broader duty point spans that are highly competitive in terms of price, durability, and performance," says Morten Christian Larsen, Managing Director at Svanehoj Singapore. A fundamental shift in mindset The new NCM Engine Room Pump is a testament to Svanehøj’s strong tradition of marine pump innovation and its commitment to supporting the industry in powering a better future. The lightweight, compact design and minimal maintenance requirements reduce the pump’s overall environmental footprint while also improving working conditions for the crew onboard. Ship’s efficiency and overall operation "This is much more than just another pump design. It represents a fundamental shift in mindset and a complete relaunch, simplifying and strengthening our entire marine pump program," says Morten Christian Larsen, adding "Engine room pumps are critical to a ship’s efficiency and overall operation, and we firmly believe there is room in the market for a design that is fully optimised across the entire value chain, from manufacturing and installation to operation and maintenance." Once fully implemented, the new NCM Engine Room Pump series will enable Svanehøj to cover the full range of up to 1,500 m³ in capacity and up to 12 bar pressure with just 16 pump variants, significantly reducing complexity in engine room planning.

Dutch maritime solar innovator - Wattlab has delivered a solar energy system for HGK Shipping’s inland shipping cargo vessel - Blue Marlin. Representing a major technical milestone and step forward for sustainable inland shipping, the vessel’s 192 solar panels will provide power to both the onboard and propulsion systems, making the Blue Marlin the first inland shipping vessel in the world capable of hybrid sailing with solar power. Broad maritime experience HGK Shipping is a European inland waterway shipping company operating a fleet of 350 vessels HGK Shipping is a European inland waterway shipping company operating a fleet of 350 vessels. With annual freight figures in the region of 43 million tonnes, HGK Shipping is considered to be a pioneering player in European dry bulk, gas and chemical transport. Wattlab, which is also active in the seagoing shipping industry, brings broad maritime experience to this pioneering project. Wattlab has worked previously with HGK Shipping. In Q2 2024, HGK’s 135-metre-long dry cargo vessel MS Helios made headlines – and entered The Guinness Book of Records – for having the world’s largest solar panel installation on an inland shipping vessel. The MS Helios is equipped with 312 solar panels. Fully integrated system The solar energy systems of the Helios and the Blue Marlin differ in one critical aspect. Unlike the Helios, where solar energy was used exclusively for low-voltage onboard (hotel) systems, the Blue Marlin features a more advanced, fully integrated system capable of contributing power directly to the ship’s high-voltage electric propulsion. This, says Wattlab Co-Founder and COO, David Kester, is a technical milestone. “The Blue Marlin’s 192 solar panels are not only connected to the low-voltage onboard systems but also to the high-voltage propulsion network. This means that HGK Shipping can proudly state that they are the first inland shipping company to operate a vessel that uses solar power directly for propulsion.” Automated energy management Blue Marlin’s solar power system will operate in conjunction with four diesel generators Delivering up to 35 kilowatts under optimal conditions, the Blue Marlin’s solar power system will operate in conjunction with four diesel generators powering the electric propulsion system. This fully integrated setup enables ‘peak shaving’, where the combination of solar energy and batteries will prevent the need for activating an additional generator during high-demand periods. The system’s automated energy management will distribute electrical energy where and when it is required, increasing efficiency and reducing fuel consumption. “Furthermore, in situations where the ship is lightly loaded and travelling downstream, we anticipate that it may even sail using only solar power for limited periods — an unprecedented achievement in the inland shipping sector,” continues David Kester. Proud to pioneer "We have already reached a significant technical milestone with the construction of the Helios, which has had a noticeably positive impact. The Blue Marlin now goes one step further by also using solar energy for the power train. It makes another important contribution to making shipping, which is already a low-emission mode of transport, even more sustainable. We are excited to see how this innovative solution will prove itself in practical operation,” says Tim Gödde, Director Ship Management at HGK Ship Management Lux S.à r.l. He adds, “We are proud to pioneer the use of solar propulsion in inland shipping. The Blue Marlin demonstrates what’s possible when innovation meets engineering expertise.” Blue Marlin’s solar panels Installation of the Blue Marlin’s solar panels took place at De Gerlien van Tiem shipyard, with Wattlab Installation of the Blue Marlin’s solar panels took place at De Gerlien van Tiem shipyard, with Wattlab cooperating closely with Blommaert Aluminium and Van Tiem Electro. “We have been working with these partners for some time now – on multiple vessels – so have managed to really optimise the processes. The Blue Marlin is a new-build vessel; it took about one week for installation followed by a few days for commissioning,” said David Kester, adding “Considering a similar-sized retrofit project, we estimate that a shipowner would be looking at a downtime of no more than one week.” Scalable solar solutions for coastal and seagoing vessels This project also marks a broader evolution in maritime decarbonisation strategies. As regulatory pressure increases and fuel prices fluctuate, shipowners and operators are looking to diversify their energy mix. Wattlab’s scalable solar solutions are proving their viability not only on inland waterways, but also on coastal and seagoing vessels.

ABB has signed a 15-year service agreement with Royal Caribbean Group, a vacation industry pioneer with a global fleet of 67 ships across its five brands travelling to all seven continents, deepening the long-standing partnership to support the company’s ship performance goals. Covering 33 existing ships, the comprehensive agreement includes preventive maintenance and digital solutions to support and optimise propulsion operations, improve vessel safety, maximise fleet availability, and ensure fast turnaround times for planned Azipod® propulsion servicing. Financial terms were not disclosed. Installation of Azipod® propulsion “Our collaboration with Royal Caribbean Group spans nearly three decades, beginning with the installation of Azipod® propulsion on one of the world’s largest cruise ships at the time,” said Juha Koskela, President of ABB’s Marine & Ports division. “Since then, we’ve partnered on numerous pioneering projects. This service agreement marks an important milestone in our journey together and highlights the critical role of ABB’s solutions in modernising and maintaining the performance of one of the world’s most innovative cruise fleets.” Revolutionised marine transport Azipod® propulsion has revolutionised marine transport by delivering unparalleled gains for performance “This agreement exemplifies how a shared commitment to innovation can unlock new opportunities to improve progress toward ship performance goals,” said Palle Laursen, Royal Caribbean Group EVP and Head of Marine. From its creation over three decades ago to its pioneering position in shipping, Azipod® propulsion has revolutionised marine transport by delivering unparalleled gains for performance, efficiency, sustainability and reliability. Vessel manoeuverability and efficiency The gearless, steerable propulsion system, with the electric drive motor in a pod outside the ship’s hull, can rotate 360 degrees to increase vessel manoeuverability and efficiency, while cutting fuel consumption by up to 20 percent compared to conventional shaftline systems. Since the first installation on a cruise ship over 25 years ago, Azipod® technology has saved more than one million tons of fuel in the cruise segment alone.

Anemoi Marine Technologies, a pioneer in wind-assisted propulsion technology, has developed an in-service performance verification process that reduces cost and complexity for operators while improving accuracy compared to existing practices. The new methodology aims to enable greater uptake of the climate-neutral, energy-saving advantages of wind-assisted propulsion. Rotor sail system The data is used to calibrate predictions on forces generated by the rotor sail system The process, validated by the class society Lloyd’s Register Advisory, involves measuring vessel data when the wind-assisted propulsion system is turned on and off while encountering various conditions during regular operation. The data is used to calibrate predictions on forces generated by the rotor sail system and their impact on the vessel, which can be used to predict voyage fuel savings with high levels of confidence. Evaluation of wind-assisted propulsion systems Anemoi Technical Director, Luke McEwen, said: “With this paper, our aim is to bring greater transparency and consistency to the evaluation of wind-assisted propulsion systems. By describing our performance assessment methodology in detail, we hope to contribute meaningfully to the wider industry discussion and move closer to a standardised framework that enables clear, comparable results across all WAPS technologies." "While various approaches exist, a unified standard will be key to supporting informed decision-making and accelerating decarbonisation in shipping.” Challenges of applying traditional methodologies Lloyd’s Register Advisory confirmed that these benefits are accrued while improving the accuracy of overall fuel saving The methodology - published in the new whitepaper, Performance Verification Of Wind-Assisted Ship Propulsion Systems By On-Off Testing - can be used for all wind-assisted propulsion solutions, not just Anemoi’s Rotor Sails. It overcomes the challenges of applying traditional methodologies, such as ISO 19030, to WAPS assessment and eliminates costly operational changes, such as taking vessels off hire to perform dedicated WAPS sea trials, which are proposed by some standards. Lloyd’s Register Advisory confirmed that these benefits are accrued while improving the accuracy of overall fuel saving predictions. Wind-assisted propulsion verification Lloyd’s Register Advisory Ship Performance Manager, Dr. Santiago Suarez de la Fuente, added: “The current standards and guidelines around wind-assisted propulsion verification are relatively sparse, and an opportunity exists for a process that is robust, widely adopted, and transparent." "Anemoi’s methodology achieves this, allowing for predictions of performance to be applied to the entire range of conditions that a vessel and the system will encounter, without tests needing to be conducted in every condition.” Fuel savings of WAPS-equipped vessels The model developed using Anemoi’s process can be used throughout the life of the vessel to generate accurate fuel savings values, either in real time or on a voyage-by-voyage basis. It also enables the creation of advanced predictive tools that can estimate the power and fuel savings of WAPS-equipped vessels in a wide range of conditions. Net propulsion fuel savings Anemoi and Lloyd’s Register Advisory recently announced the results of the TR Lady Kamsarmax Anemoi and Lloyd’s Register Advisory recently announced the results of the TR Lady Kamsarmax, equipped with three of Anemoi’s 5m diameter, 24m tall Rotor Sails, assessed using the methodology outlined in the paper. Following a year-long, multi-voyage testing period, the robust approach demonstrated average net propulsion fuel savings of 9.1% and 7 tonnes of CO2e per sailing day. On-ship performance of technologies Commenting on the TR Lady’s performance testing, Chris Hughes, Decarbonisation Specialist at Cargill, the vessel’s charterer, said: “Building up an accurate understanding of the real-world, on-ship performance of technologies is a key piece in the wind assist propulsion puzzle. By combining the data from more than 167 rotor on/off tests that were conducted by the TR Lady, together with the independent verification from LR, Anemoi instilled confidence in the accuracy of their analysis." "We have already used the results of this study to fine-tune our weather routeing digital twins for TR Lady, and it will also help inform future decisions on deploying wind assist across our fleet.”

IMTRA, the globally renowned manufacturer and importer of quality solutions and products for the marine, energy and transportation markets, announced the introduction of the newest innovation in vessel pitch and roll control, Zipwake PRO. IMTRA is the exclusive distributor for Zipwake in the U.S. Zipwake PRO is the ultimate upgrade to Zipwake’s award-winning Dynamic Trim Control System. Zipwake Series S or E systems Zipwake PRO offers significant gains in version and precision for better acceleration Available for new installations and as an enhancement to existing Zipwake Series S or Series E systems, Zipwake PRO brings Active Pitch Control, improved Active Roll, Balanced and Coordinated turning and Wake Shaping functionality to boaters for perfect trim stability in any conditions. Featuring interceptors that move five times faster than legacy Zipwake systems, Zipwake PRO offers significant improvements in performance and precision for better acceleration, stability, comfort and lower fuel consumption. The system’s 0.3 second blade rate brings quicker adjustments, allowing the system to respond rapidly to changing conditions and optimise a boat’s handling. Next evolution in vessel control "We’re excited to introduce the next evolution in vessel control and comfort on the water with Zipwake PRO," said Jamie Simmons, IMTRA’s Zipwake Product Manager, adding "Zipwake’s Dynamic Trim Systems have been proven time and time again with over 60,000 installations globally." Jamie Simmons adds, "With features like Active Pitch Control and Active Roll and so much more, Zipwake PRO enhances the comfort of passengers and guests, while adding to the fun on the water in any application from cruising to wakeboarding and everything in between." Zipwake PRO features Balanced turn (coordinated turn) is now sharper, more precise and even faster with Zipwake PRO Zipwake PRO features Active Pitch, which allows continuous and rapid adjustments to the boat’s trim to maintain the pitch angle set by the user. Regardless of head seas, following seas, beam seas or changes in weight distribution, the system constantly works to keep the boat at the optimal running trim angle. Active Roll is another enhanced feature in the Zipwake PRO system. The ultra-fast interceptors ensure quicker, more precise corrections to rolling motions caused by changing conditions for greater passenger comfort. Balanced turn (coordinated turn) is now sharper, more precise and even faster with Zipwake PRO. System’s wake-shaping feature The system dynamically adjusts heeling angle, ensuring smoother, controlled turns at any speed. For those that enjoy tow and surf sports, the system’s wake-shaping feature provides easy control for fine-tuning wakes and creating ideal surfing conditions. In addition, Zipwake PRO has an adaptive interface that intelligently adjusts to display relevant information delivering a user-friendly experience for precise motion control. It also integrates with third-party MFDs. Local boatyards or marine equipment installers Distributed exclusively in the U.S. by IMTRA, Zipwake PRO is available in 25 different models, the widest range of interceptors available on the market today, with systems for boats from 20-feet to 100-feet in length. The Zipwake PRO system will be available this summer through local boatyards or marine equipment installers and backed by IMTRA’s renowned pre- and post-sales support.

The hull of the state-of-the-art DP3 cable-laying vessel - Nexans Electra arrived at Ulstein Verft on 5 July 2025. This marks the commencement of the outfitting and completion phase of the vessel. Upon completion in 2026, she will feature a split turntable on deck capable of holding up to 10,000 tonnes of cable, an under-deck turntable with a 3,500-tonne cable capacity, and a fibre optic tank with a 450-tonne capacity. Ulstein Verft and Nexans Ulstein Verft will also install the main parts, including the main generator set, power package The shipbuilding contract between Ulstein Verft and Nexans, a pure player in sustainable electrification and a pioneer in subsea cable systems, was signed in 2023. The hull has been under construction at the Crist yard, Poland. The hull will now be towed into the dock hall at Ulstein Verft, where outfitting, electrical work, insulation, and piping will commence. Ulstein Verft will also install the main components, including the main generator set, power package, deck machinery, winches, and topside equipment. Prepared for the future The Nexans Electra measures 155.2 metres in length and 31 metres in beam. She will be equipped for safe and efficient transport and installation of large volumes of HVDC and HVAC cable systems, as well as complex subsea construction tasks in deep waters. The vessel's built-in structural and system capacities, along with flexible design features, will allow easy adaptation to future customer needs. Large capacity and high capabilities Nexans Electra is based on the Nexans Aurora, which was delivered by Ulstein Verft in 2021 The Nexans Electra, designed by Skipsteknisk, is based on the Nexans Aurora, which was delivered by Ulstein Verft in 2021. She is specifically designed to transport and lay Nexans submarine products, including cable bundles, as well as perform recovery and repair of such products. The vessel can perform effectively in challenging weather conditions and boasts exceptional manoeuvrability and station-keeping characteristics. The incorporation of high-capacity shore power systems, an energy storage system, and biofuel compatibility ensures a reduced environmental footprint. Based on combined expertise The vessel has been developed through the combined experience of Nexans, Skipsteknisk, the Ulstein Verft yard, and NOV Remacut, each a pioneer in their respective fields. This collaboration has produced a Cable Lay Vessel for worldwide operations, covering the full range of shallow and deep subsea activities.

Expert commentary

Marine industry pioneers gathered at Nor-Shipping in June, with a focus on the key challenges and opportunities driving the transition to a lower-carbon future. With regulations such as the Carbon Intensity Indicator (CII), FuelEU Maritime, the EU Emissions Trading System (EU ETS) and the upcoming International Maritime Organisation (IMO) carbon levy, fouling control systems continue to play a vital role in the shipping industry as the regulatory bodies chart a course towards net-zero emissions by 2050. Fouling control systems Vessel operators will have to navigate a new challenge on the horizon after a global deal agreement These fouling control systems help reduce fuel consumption and CO₂ emissions, enabling vessels to maintain favourable efficiency ratings and avoid penalties. Vessel operators will have to navigate a new challenge on the horizon after a global deal agreement was passed at the UN's IMO MEPC 83 meeting in April, following almost a decade of negotiations. Carbon-intensive fuels From 2028, owners of large vessels will have to reduce their carbon-intensive fuels or face fines of up to $380 per tonne of carbon dioxide emissions from burning fuel. Shipping has become the first industry in the world with internationally mandated targets to reduce emissions and according to maritime consultancy UMAS, the historic agreement could result in an eight percent reduction in emissions by 2030. Fouling control coatings Vessel operators need to consult coating companies with proven expertise in fouling control coatings The deal is a historic moment for the industry and will further drive home the importance of cutting fuel consumption. Marine coatings and technologies, in isolation, are not enough for shipowners to comply with the regulations. Vessel operators need to consult coating companies with proven expertise in high-performing fouling control coatings and a strong track record of in-service performance, to support data-driven and well-informed investment decisions. Underwater hull schemes We’ve supported customers with their CII ratings and have helped them offset the EU ETS surcharge, which came into effect last year. In 2024, shipowners were responsible for 40% of their emissions costs, increasing to 70% this year and set to reach 100% from 2026. Last year, a record number of customers engaged with us to identify the most suitable underwater hull schemes to aid CII compliance, highlighting the growing demand for tailored fouling control solutions from International® marine coatings. Our solutions not only ensure regulatory compliance but also enhance vessel performance and sustainability. Vessel fuel consumption and CO2 emissions Application of Intercept® 8500 LPP on a trading VLCC vessel led to a removal of carbon emissions For example, the application of Intercept® 8500 LPP on a globally trading VLCC vessel led to a reduction of carbon emissions of approximately 8,500 tonnes over the five years in service. As a result, this vessel maintained a CII ‘A’ grade rating throughout the study, which resulted in the customer achieving both performance and decarbonisation targets. Furthermore, we have seen increased demand for Intertrac® Vision, our big data prediction tool that enables ship owners and operators to assess the impact of fouling control coatings on vessel fuel consumption and CO2 emissions while in transit. This digital tool allows our experts to collaborate closely with vessel operators to assess the return on investment of various coating schemes, tailored to vessel type and operating conditions. It simplifies the coatings selection process and delivers data-driven insights for more informed decision-making. Hull performance expertise and data-driven insights The carbon levy passed at the IMO meeting in April is scheduled for implementation in 2028. With steeper penalties, it is expected to impact global shipping routes if vessel operators do not reduce their reliance on carbon-intensive fuels. However, there are steps that shipowners can take to invest in regulation compliances and minimise penalties. With nearly 150 years of experience serving the marine industry, offering high-performance coatings, hull performance expertise and data-driven insights, we are uniquely positioned to help shipowners achieve regulatory compliance while maintaining operational efficiency.

Demand for ammonia is being transformed by the energy transition. Until recently used as an input for fertiliser and chemical products, new markets for green and blue ammonia are emerging, replacing fossil energy in power generation, steel production and marine fuel. Today some 200m tonnes per annum of ammonia is produced worldwide with 20m tpa transported in LPG carriers. The scale of the emerging and potential demand will see these figures rise; how quickly this can be achieved will determine its take-up as a shipping fuel. New or evolving technology The interest in ammonia stems both from its ‘zero emissions’ when used as fuel and because its production isn’t dependent on biogenic carbon sources. As the global economy transitions away from fossil-based fuels, biogenic carbon – from captured CO2, electrolysis and even waste sources – will be subject to increasing competition from other consumers. Shipyards around the world are considering the advantages that operating on ammonia may provide Accordingly, owners, operators, designers, and shipyards around the world are considering the advantages that operating on ammonia may provide. However, when considering any new or evolving technology, it is important to have a clear understanding of not only the benefits, but the challenges that may be involved. Challenges of ammonia bunkering Biogenic carbon will increasingly replace fossil-based carbon in many of the products in use today in industry and consumer goods. Competition from the energy and aviation sectors will inevitably lead to increased prices but production capacity will need to come from industrial sources rather than biomass harvested for this purpose. ABS has produced a Technical and Operational Advisory on Ammonia Bunkering in response to the need for better understanding by members of the maritime industry. It is intended to provide guidance on the technical and operational challenges of ammonia bunkering, both from the bunker vessel’s perspective (or land-side source) and from the receiving vessel’s perspective. Managing emissions Particular attention needs to be paid to the potential presence of ammonia slip, N2O or NOx emissions The carbon emissions from the combustion of ammonia are associated with and dependent on the type and amount of pilot fuel used. The use of biofuel as pilot fuel may further reduce the emissions. In addition, the emissions of sulphur dioxide, heavy metals, hydrocarbons, and polycyclic aromatic hydrocarbons (PAHs) drop to zero (or near zero, depending on the pilot fuel used); and particulate matters (PM) are also substantially reduced compared to conventional fossil fuels. However, particular attention needs to be paid to the potential presence of ammonia slip, N2O or NOx emissions, due to the imperfect combustion of ammonia and the use of pilot fuels. These emissions will need to be kept as low as possible by further adjustment and development of the engine technology or using an on-board exhaust gas treatment technology. Currently, hydrogen for ammonia production is typically produced by means of steam methane reforming (SMR) or autothermal reforming (ATR) of natural gas (grey ammonia). If the CO2 emissions from the process of converting natural gas are captured and stored, the ammonia is typically referred to as ‘blue’. Production of blue ammonia Moreover, the production of blue ammonia retains a dependency on fossil fuels. Therefore, ‘green ammonia’, which is produced from hydrogen made from renewable energy sources (green hydrogen), is generally considered to be the end-solution for decarbonisation which leads to a sustainable fuel cycle, while blue ammonia is seen to have an intermediate role. The potential well-to-wake GHG emissions of green ammonia are estimated to be around 91% lower than for grey ammonia, and 85% lower than HFO and MGO. The grey ammonia production network is already well established and global, ensuring easier accessibility across major ports worldwide. Infrastructure and regulation Specific requirements for ammonia bunkering are under discussion by all marine stakeholders This will help green ammonia become readily available for bunkering and distribution once sufficient production and infrastructure are in place. On the other hand, when compared with liquid hydrogen or LNG which can be stored at temperatures of −253°C and −162°C, respectively, liquid ammonia can be stored and transported at −33°C near atmospheric pressure, which allows for easier adaptation of existing fuel infrastructure on ships and at ports. While specific requirements for ammonia bunkering are under discussion by all marine stakeholders, the requirements for shipping ammonia as cargo, including loading and unloading operations, have been established in the marine industry and are covered by the IMO International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk (IGC Code) and incorporated in the ABS Rules for Building and Classing Marine Vessels Part 5C Chapter 8 “Vessels Intended to Carry Liquefied Gases in Bulk”. For the use of ammonia as bunker fuel, all segments of the marine industry (including IMO, Class Societies, Port Authorities, and industry agencies) are working to develop requirements and procedures specific to ammonia bunkering operations. Refer to the section “Regulatory Organisation” of this Advisory for the current activities of each marine industry segment. Bunkering Options Ship-to-ship bunkering is the most popular mode for transferring fuel to ocean-going vessels There are three main methods of bunkering ammonia to ships. Truck-to-ship is the process of transferring ammonia from trucks or truck trailers to a receiving vessel using ammonia as fuel. Typically, the tanks on the truck are pressurised and store ammonia at ambient temperature. To increase bunker capacity and transfer rates, a manifold may be used to connect several trucks simultaneously to supply the receiving vessel. Truck-to-ship transfer operations may provide greater operational flexibility, but at the same time could induce operational restrictions and limitations by the local Authority. Ship-to-ship bunkering is the most popular mode for transferring fuel to ocean-going vessels, such as container ships, tankers, and bulk carriers, which require large fuel capacities and greater quantities of fuel to be bunkered. Terminal-to-ship bunkering transfers ammonia from an ammonia storage terminal pipeline connected to receiving vessels via a hose assembly or loading arm. Ammonia Safety Ammonia is toxic and reacts violently and explosively with oxidising gases such as chlorine, bromine, acids, and other halogens. When ammonia is inhaled, swallowed or absorbed via skin contact, it reacts with water in the body, producing ammonium hydroxide. Due to these toxicity issues, ammonia is classified as a hazardous substance, with the level and time of exposure being controlled by several national standards. The level of competency needed for each task depends on the role and duties of the individual A combination of both training and operational experience is key to developing the required competencies for ammonia bunkering operations. The level of competency needed for each task depends on the role and responsibilities of the individual. Therefore, the training may vary from person to person. Seafarers on board ships using ammonia fuel should have completed training to attain the abilities that are appropriate to the capacity to be filled, and duties and responsibilities to be taken up. The master, officers, ratings and other personnel on ships using ammonia fuel should be trained and qualified in accordance with regulation V/3 of the STCW Convention and section A-V/3 of the STCW Code, taking into account the specific hazards of ammonia used as fuel. Ship-specific training Ship-specific training is to be reviewed and approved by governing regulatory authorities. The IGF Code provides detailed training requirements for ships that use gases or other low-flashpoint fuels. Ships under the jurisdiction of flag administrations signatory to SOLAS should ensure that seafarers should have the specified certificates of proficiency and the administration shall approve courses and issue endorsements indicating completion of the qualification. All crew must be provided with and be made aware of the emergency procedures and must be trained in any roles and responsibilities they may have. Training, drills and exercises to prepare crews for emergencies are to be provided. Lessons learned from past operations should be incorporated to improve emergency procedures. Procedures should cover all scenarios specific to the ship, type of incident, equipment, and associated areas.

Global transportation networks are becoming increasingly interconnected, with digital systems playing a crucial role in ensuring the smooth operation of ports and supply chains. However, this reliance on technology can also create vulnerabilities, as demonstrated by the recent ransomware attack on Nagoya Port. As Japan's busiest shipping hub, the port's operations were brought to a standstill for two days, highlighting the potential for significant disruption to national economies and supply chains. Transportation sector The attack began with the port's legacy computer system, which handles shipping containers, being knocked offline. This forced the port to halt the handling of shipping containers that arrived at the terminal, effectively disrupting the flow of goods. The incident was a stark reminder of the risks associated with the convergence of information technology (IT) and operational technology (OT) in ports and other critical infrastructures. This is not an isolated incident, but part of a broader trend of escalating cyber threats targeting critical infrastructure. The transportation sector must respond by bolstering its defences, enhancing its cyber resilience, and proactively countering these threats. The safety and efficiency of our transportation infrastructure, and by extension our global economy, depend on it. Rising threat to port security and supply chains XIoT, from sensors on shipping containers to automatic cranes, are vital to trendy port functions OT, once isolated from networked systems, is now increasingly interconnected. This integration has expanded the attack surface for threat actors. A single breach in a port's OT systems can cause significant disruption, halting the movement of containers and impacting the flow of goods. This is not a hypothetical scenario, but a reality that has been demonstrated in recent cyberattacks on major ports. Adding another layer of complexity is the extended Internet of Things (XIoT), an umbrella term for all cyber-physical systems. XIoT devices, from sensors on shipping containers to automated cranes, are now integral to modern port operations. These devices are delivering safer, more efficient automated vehicles, facilitating geo-fencing for improved logistics, and providing vehicle health data for predictive maintenance. XIoT ecosystem However, the XIoT ecosystem also presents new cybersecurity risks. Each connected device is a potential entry point for cybercriminals, and the interconnected nature of these devices means that an attack on one, which can move laterally and can have a ripple effect throughout the system. The threat landscape is evolving, with cybercriminals becoming more sophisticated and their attacks more damaging with a business continuity focus. The growing interconnectivity between OT and XIoT in port operations and supply chains is also presenting these threat actors with a greater attack surface. Many older OT systems were never designed to be connected in this way and are unlikely to be equipped to deal with modern cyber threats. Furthermore, the increasing digitisation of ports and supply chains has led to a surge in the volume of data being generated and processed. This data, if not properly secured, can be a goldmine for cybercriminals. The potential for data breaches adds another dimension to the cybersecurity challenges facing the transportation sector. Role of cyber resilience in protecting service availability Cyber resilience refers to organisation's ability to prepare for, respond to, and recover from threats As the threats to port security and supply chains become increasingly complex, the concept of cyber resilience takes on a new level of importance. Cyber resilience refers to an organisation's ability to prepare for, respond to, and recover from cyber threats. It goes beyond traditional cybersecurity measures, focusing not just on preventing attacks, but also on minimising the impact of attacks that do occur and ensuring a quick recovery. In the context of port operations and supply chains, cyber resilience is crucial. The interconnected nature of these systems means that a cyberattack can have far-reaching effects, disrupting operations not just at the targeted port, but also at other ports and throughout the supply chain. A resilient system is one that can withstand such an attack and quickly restore normal operations. Port operations and supply chains The growing reliance on OT and the XIoT in port operations and supply chains presents unique challenges for cyber resilience. OT systems control physical processes and are often critical to safety and service availability. A breach in an OT system can have immediate and potentially catastrophic physical consequences. Similarly, XIoT devices are often embedded in critical infrastructure and can be difficult to patch or update, making them vulnerable to attacks. Building cyber resilience in these systems requires a multi-faceted approach. It involves implementing robust security measures, such as strong access controls and network segmentation, to prevent attacks. It also involves continuous monitoring and detection to identify and respond to threats as they occur. But perhaps most importantly, it involves planning and preparation for the inevitable breaches that will occur, ensuring that when they do, the impact is minimised, and normal operations can be quickly restored. Building resilience across port security and supply chains In the face of cyber threats, the transport sector must adopt a complete method of cybersecurity In the face of escalating cyber threats, the transportation sector must adopt a comprehensive approach to cybersecurity. This involves not just implementing robust security measures, but also fostering a culture of cybersecurity awareness and compliance throughout the organisation. A key component of a comprehensive cybersecurity strategy is strong access controls. This involves ensuring that only authorised individuals have access to sensitive data and systems. It also involves implementing multi-factor authentication and regularly reviewing and updating access permissions. Strong access controls can prevent unauthorised access to systems and data, reducing the risk of both internal and external threats. Network segmentation Network segmentation is another crucial measure. By dividing a network into separate segments, organisations can limit the spread of a cyberattack within their network. This can prevent an attack on one part of the network from affecting the entire system. Network segmentation also makes it easier to monitor and control the flow of data within the network, further enhancing security. Regular vulnerability assessments and patch management are also essential. Vulnerability assessments involve identifying and evaluating potential security weaknesses in the system, while patch management involves regularly updating and patching software to fix these vulnerabilities. These measures can help organisations stay ahead of cybercriminals and reduce the risk of exploitation. EU’s NIS2 Directive EU’s NIS2 Directive came into effect, and member states have until October 2024 to put it into law The transportation sector must also be prepared for greater legislative responsibility in the near future. The EU’s NIS2 Directive recently came into effect, and member states have until October 2024 to put it into law. The Directive aims to increase the overall level of cyber preparedness by mandating capabilities such as Computer Security Incident Response Teams (CSIRTs). Transport is among the sectors labelled as essential by the bill, meaning it will face a high level of scrutiny. Getting to grips with the complexities of XIoT and OT integration will be essential for organisations to achieve compliance and avoid fines. Global transportation infrastructure Finally, organisations must prepare for the inevitable breaches that will occur. This involves developing an incident response plan that outlines the steps to be taken in the event of a breach. It also involves regularly testing and updating this plan to ensure its effectiveness. A well-prepared organisation can respond quickly and effectively to a breach, minimising its impact and ensuring a quick recovery. In conclusion, mastering transportation cybersecurity requires a comprehensive, proactive approach. It involves implementing robust technical measures, fostering a culture of cybersecurity awareness, and preparing for the inevitable breaches that will occur. By taking these steps, organisations can enhance their cyber resilience, protect their critical operations, and ensure the security of our global transportation infrastructure.

Harbour insights

Electrification plays an important role in addressing the environmental challenges facing the maritime sector, and electric propulsion is the key component in this transition. Energy-efficient propulsion, which encompasses both efficient drivetrain and less weight, will contribute to meeting environmental challenges, while providing unwavering reliability for the operators. Cleaner propulsion solutions Ease of integration and maintenance helps streamline system design and installation, crucial factors in speeding up the adoption of cleaner propulsion solutions across the maritime sector. ABB promotes the adoption of advanced motor technologies in the rail, marine, and eMobility sectors through the Traction & Mobile e-Power Motors business unit. The team designs and delivers both components and complete propulsion systems for railway as well as off-highway machines and marine markets. IMO’s 2050 net-zero goals ABB helps the IMO’s 2050 net-zero goals by advancing marine electrification via innovations “The energy-efficient solutions we've developed are enabling compact, reliable electric propulsion in marine applications exemplified by our new AMXE Marine Motor, engineered specifically to meet the harsh demands and specific requirements of the marine market and environment,” says Henrik T. Nilsson, Global Sales Manager for Traction & Mobile e-Power Motors. ABB supports the IMO’s 2050 net-zero goals by advancing marine electrification through innovations like the AMXE Marine Motor and advanced motor control technologies. Conventional propulsion systems This compact, high-power-density AMXE Marine Motor is designed for small to mid-sized electric and hybrid vessels and open deck applications, offering high efficiency, low weight and excellent performance in a durable frame designed to sustain marine environments. By replacing conventional propulsion systems, the AMXE enables cleaner, more sustainable vessel operations. ABB’s global expertise, service network, and complementary technologies further enhance marine efficiency and decarbonisation, says Nilsson. These solutions help shipbuilders and operators meet sustainability targets and transition toward low emission. ABB’s expertise in the marine industry AMXE Marine Motor, which ABB gave at Nor-Shipping in June, uses technologies set for off-highway equipment “ABB is pioneering the way in developing cutting-edge solutions to help the marine transport industry achieve net-zero goals,” says Nilsson. “By consistently innovating and working closely with industry partners, ABB is delivering the technologies and expertise needed to steer the industry towards a cleaner and more sustainable future.” The AMXE Marine Motor, which ABB presented at Nor-Shipping in June, uses technologies developed for off-highway equipment, such as mining trucks or electric buses, combined with a durable design that encompasses ABB’s expertise in the marine industry. ABB’s motor portfolio This resulted in a motor with the highest power density in ABB’s motor portfolio, delivering more power with less weight and space. It is housed in a frame that is compliant with industry standards, including corrosion protection to withstand tough environments. Pairing the motor with ABB inverters like the HES880 Mobile Inverter creates efficient, responsive propulsion systems designed to meet the demands of the next generation of electric and hybrid vessels. ABB’s HES880 Mobile Designed for harsh climates, ABB’s HES880 Mobile rugged, liquid-cooled inverter offers high efficiency The new AMXE Marine Motor offers the highest power density in ABB’s motor portfolio. Its lightweight, compact design makes it more energy-efficient than traditional combustion systems. When paired with ABB drives, it helps to lower energy consumption, boost performance, and reduce operational costs. Designed for harsh environments, ABB’s HES880 Mobile rugged, liquid-cooled inverter offers high efficiency, IP67 protection and a corrosion-resistant enclosure. Its multifunctional use, maintenance-free build, and compact design make it suitable for electrifying heavy-duty applications like vessels. ABB’s experience in marine applications Drawing on ABB’s experience in mining, rail, and marine applications, the AMXE Marine Motor is built to deliver long-lasting, high-performance operation in tough maritime environments. It's fully enclosed water-cooled design reduces noise while enhancing comfort and reliability. Engineered with a robust well-proven insulation system, and a design that supports the installation needs of the marine industry, it ensures a long lifetime and ease of installation in most marine applications as well as machine rooms with limited space. AMXE Marine Motor Key stakeholders in transitioning to electrical marine applications include shipbuilders, vessel operators The AMXE Marine Motor has undertaken extensive validation testing, including IP, shock and vibration, corrosion resistant and validated the insulation system to comply with IVIC Class C. Key stakeholders in transitioning to electrical marine applications include shipbuilders, vessel operators, technology providers like ABB, and regulatory bodies such as the International Maritime Organization (IMO) together with the harbours that need to provide the primary charging infrastructure. Electric propulsion systems Shipbuilders integrate electric propulsion systems into vessel designs, while operators adopt and manage these technologies to improve efficiency and reduce emissions. Regulators drive industry adoption by setting the decarbonisation targets, like the IMO’s 2050 net-zero goal, driving industry adoption. Possibly the biggest challenge for companies looking to decarbonise is uncertainty around the availability and cost of alternative future energy modes. This is probably less of an issue with electrification than other alternative fuels. Availability of electricity Transitioning to electric drivetrains can help lower operating costs, increase efficiency and performance Transitioning to electric drivetrains can help lower operating costs, increase efficiency and performance, and reduce environmental impact. In general, the availability of electricity is more stable, even if work remains in the charging infrastructure for the marine market. The technologies for electric drivetrain on ships are already available and proven effective. Through continue collaboration with the stakeholders in the marine industry, a more sustainable future is possible. Decarbonisation objectives “It was great to be able to meet our customers, engage at Nor-Shipping in meaningful conversations and showcase ABB’s solutions for the marine industry,” says Nilsson. “The event theme ‘Future-Proof’ focused on sustainable solutions and innovations for the future of the maritime sector." Nilsson added: "The theme aligned with the launch of ABB’s AMXE Marine Motor. We are thrilled to provide future-proof solutions that help customers meet their decarbonisation objectives. Being relatively new in the marine industry myself, I was impressed at Nor-Shipping by the openness to new technologies and the deep understanding in the industry of how these new technologies can address current and future challenges.”