Ocean Infinity, a world pioneer in robotic and uncrewed vessel technology, is pleased to announce the signing of a Global Framework Agreement (GFA) with Shell, marking a significant milestone in the provision of lean-crewed and robotic seabed geomatics, spanning geophysical and geotechnical services, within the offshore energy sector.

The GFA spans 5 years, encompassing all countries where Shell is currently active or plans to operate in the future.

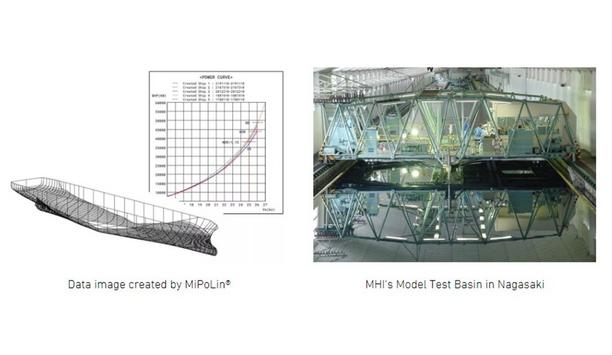

Fuel-efficient vessels

Services governed by the GFA include the Armada fleet of uncrewed and lean-crewed vessels. Designed for today’s tasks but with tomorrow in mind, the fleet of exceptionally fuel-efficient vessels only utilise a skeleton crew onboard, with data processing and payload control conducted from onshore Operations Centres.

In due course, they will be capable of working with no personnel offshore whilst also consuming solely renewable fuel such as ammonia.

Surface robotics

The partnership with Shell has evolved into a robust collaboration based on a shared vision

With a history dating back to Ocean Infinity’s inception, the partnership with Shell has evolved into a robust collaboration based on a shared vision for transformative ways of working.

The journey began with a groundbreaking project in Mauritania, simultaneously utilising a fleet of Unmanned Surface Vehicles (USVs), marking the inception of surface robotics working in the oil and gas sector.

Robotic fleet

Katya Krylova, VP of Business Development at Ocean Infinity, said "This agreement enables new, lean-crewed vessels into high-value fieldwork. Using our robotic fleet to service global offshore energy activities will power the maritime industry’s transformation into safer, more efficient new ways of working."

She adds, "It also solidifies a long-standing and valued collaboration between Shell and Ocean Infinity."

Flexibility and scalability

Katya Krylova continues, "Working through framework agreements like this allows us to achieve shorter lead times, reduce risks, improve strategic alignment together with flexibility and scalability, work faster, and ultimately supply our partners with their data more quickly."

She concludes, "It enables us to optimise resources, making for more efficient and sustainable operations, such as by positioning our fleet more effectively to reduce transit times to and from work sites."